| Tin Lead Solder Wire 40 60, scientifically known as Solder Wire Sn40Pb60, is a soldering materialcomposed of 40% tin (Sn) and 60% lead (Pb). Solder Wire 40 60 is meticulously formulated by blending specific proportions of tin and lead, chosen for their complementary properties that contribute to effective soldering. As the results of good solderability with its affordable cost, it has been widely in many applications. |

Alloy Composition | 40% Tin (Sn), 60% Lead (Pb) |

Melting Point | 183-247°C |

Flux Type | Rosin based |

Flux Content | 2.0% as standard, or customized flux percentage |

Wire Diameter | 0.5mm to 3.2mm |

Weight | 100g/roll, 200g/roll, 500g/roll to 1kg/roll or customized weight |

Brand | XF Solder or OEM service |

*We also produce solid wire without flux core | |

Various Roll Weights |

Flux Core Wire |

Various Wire Diameters |

Medium Melting Point The solder wire 40/60 has a higher melting point than solder wire 63/37, making it suitable for components or devices that requires a bit higher working temperature. | Easy to Use Solder Wire 40 60 contains a rosin flux core, that means it can be used directly for soldering and no need to add any external flux. | |

Good Performance The solder wire Sn40Pb60 has good wetting and flowing property, it can form a round, smooth and form solder joints. | Cost Effective The cost solder wire 40 60 is much lower than solder wire 63/37 or lead free solders, it can cut down the manufacturing cost. |

Electronics and electrical devices production: that is mainly for assembly for all types of PCB and joinery for different IC components together. Such as home appliances, wearable electronics devices, electrical parts etc.

General soldering purpose: That is for some repairing work of electronics or electrical products, and some small projects of lobbyists.

Plumbing system: it's used to join the copper pipes and copper fittings for the plumbing systems.

Radiators: it's used for assembling the copper and brass radiator end plates.

Stained Glass: it's used for soldering of the lead came of the stained glass for create shapes and looks.

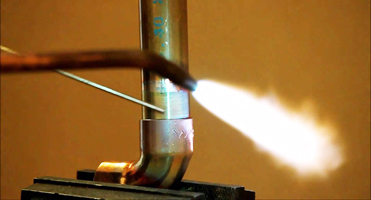

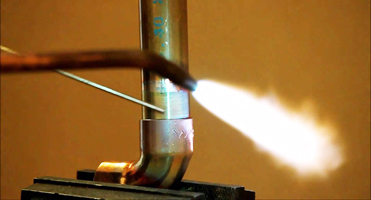

Raditator Soldering |  Plumbing Soldering Plumbing Soldering |

Electronics Soldering |

When using solder wire 40 60 for electronics assembly, we recommend to use the rosin flux core type. It's a handy formula that contains flux inside the wire, and there is no need to apply external flux when doing the soldering task. We will need soldering irons or soldering stations to carry out the soldering process.

When suing solder wire Sn40Pb60 for plumbing systems or radiators assembly, we recommend to use the solid wire without flux core, and then prepare compatible strong flux in separate for the soldering. And we will need torch gun to do this soldering process.

Use in a Well-Ventilated Area: Always solder in a well-ventilated space, such as a fume hood or near an open window, and use exhausting fan. Proper ventilation helps to dissipate harmful fumes and reduce the risk of inhaling lead vapors.

Wear Personal Protective Equipment (PPE): Consider wearing appropriate personal protective equipment, including safety glasses, gloves, and a lab coat or apron, to minimize skin and eye contact with solder and flux.

Avoid Ingestion and Hand-to-Mouth Contact: Never eat, drink, or smoke while working with leaded solder. Wash your hands thoroughly after handling solder and before eating or touching your face.

| Tin Lead Solder Wire 40 60, scientifically known as Solder Wire Sn40Pb60, is a soldering materialcomposed of 40% tin (Sn) and 60% lead (Pb). Solder Wire 40 60 is meticulously formulated by blending specific proportions of tin and lead, chosen for their complementary properties that contribute to effective soldering. As the results of good solderability with its affordable cost, it has been widely in many applications. |

Alloy Composition | 40% Tin (Sn), 60% Lead (Pb) |

Melting Point | 183-247°C |

Flux Type | Rosin based |

Flux Content | 2.0% as standard, or customized flux percentage |

Wire Diameter | 0.5mm to 3.2mm |

Weight | 100g/roll, 200g/roll, 500g/roll to 1kg/roll or customized weight |

Brand | XF Solder or OEM service |

*We also produce solid wire without flux core | |

Various Roll Weights |

Flux Core Wire |

Various Wire Diameters |

Medium Melting Point The solder wire 40/60 has a higher melting point than solder wire 63/37, making it suitable for components or devices that requires a bit higher working temperature. | Easy to Use Solder Wire 40 60 contains a rosin flux core, that means it can be used directly for soldering and no need to add any external flux. | |

Good Performance The solder wire Sn40Pb60 has good wetting and flowing property, it can form a round, smooth and form solder joints. | Cost Effective The cost solder wire 40 60 is much lower than solder wire 63/37 or lead free solders, it can cut down the manufacturing cost. |

Electronics and electrical devices production: that is mainly for assembly for all types of PCB and joinery for different IC components together. Such as home appliances, wearable electronics devices, electrical parts etc.

General soldering purpose: That is for some repairing work of electronics or electrical products, and some small projects of lobbyists.

Plumbing system: it's used to join the copper pipes and copper fittings for the plumbing systems.

Radiators: it's used for assembling the copper and brass radiator end plates.

Stained Glass: it's used for soldering of the lead came of the stained glass for create shapes and looks.

Raditator Soldering |  Plumbing Soldering Plumbing Soldering |

Electronics Soldering |

When using solder wire 40 60 for electronics assembly, we recommend to use the rosin flux core type. It's a handy formula that contains flux inside the wire, and there is no need to apply external flux when doing the soldering task. We will need soldering irons or soldering stations to carry out the soldering process.

When suing solder wire Sn40Pb60 for plumbing systems or radiators assembly, we recommend to use the solid wire without flux core, and then prepare compatible strong flux in separate for the soldering. And we will need torch gun to do this soldering process.

Use in a Well-Ventilated Area: Always solder in a well-ventilated space, such as a fume hood or near an open window, and use exhausting fan. Proper ventilation helps to dissipate harmful fumes and reduce the risk of inhaling lead vapors.

Wear Personal Protective Equipment (PPE): Consider wearing appropriate personal protective equipment, including safety glasses, gloves, and a lab coat or apron, to minimize skin and eye contact with solder and flux.

Avoid Ingestion and Hand-to-Mouth Contact: Never eat, drink, or smoke while working with leaded solder. Wash your hands thoroughly after handling solder and before eating or touching your face.

The selection of solder is a foundational element in the successful assembly and repair of LED lighting systems. The eutectic 63 37 sn pb solder offers an unparalleled combination of a low melting point, excellent wettability, and joint reliability that is perfectly suited to the thermal sensitivity of LED components. By understanding the specific applications for each diameter—from the precision of 63 37 sn pb solder 1.0mm to the power of 63 37 sn pb solder 2.0mm—you can dramatically improve the quality and efficiency of your work. Packaging this superior alloy as solder in a reel, specifically in a 63 37 sn pb solder 1 kg reel, adds layers of practicality, economy, and consistency that benefit everyone from the professional production engineer to the meticulous hobbyist. Therefore, equipping your workspace with the appropriate diameter of 63 37 sn pb solder for LED Lights is not just a purchase; it is an investment in achieving superior, reliable, and professional results in all you

Our comprehensive range of 63 37 leaded wire solder for electronics is meticulously designed to meet the exacting demands of modern electronics work. The eutectic 63/37 tin-lead alloy guarantees reliable, shiny joints free from cold solder defects. The availability of both 63 37 leaded solder 0.6mm for precision tasks and 63 37 leaded solder 0.9mm for versatile general-purpose work ensures you have the right tool for every job. Furthermore, our flexible packaging—from the bulk 63 37 leaded solder 454g for professionals, to the standard 63 37 leaded solder 227g, and the accessible 63 37 leaded solder 100g for beginners—means there is a perfect option for every user and budget. Elevate your soldering work with the proven performance and quality of genuine 63 37 leaded solder.

Welcome to XF Solder, a leading manufacturer from China dedicated to producing high-quality soldering materials for the global market. We specialize in creating reliable, consistent, and performance-driven solder products that meet the rigorous demands of various industries. Our flagship product, the 60 40 Solder .032'' 1 lb spool, represents the gold standard in through-hole and general-purpose electronics assembly. This article provides a detailed overview of why this specific formulation and packaging is an indispensable inventory item for distributors, a superior choice for importers seeking quality from China, and a perfect 60 40 Solder 1 lb for Wholesale operations globally. We will explore its technical specifications, unparalleled benefits, and the strategic advantage it offers in the competitive electronics supply chain.

The combination of the proven 60 sn 40 pb alloy, the convenience of three standard diameters (1.6mm, 1.8mm, 2mm), and the economic 1lb (454g) packaging makes this product an indispensable tool for anyone involved in creating or repairing electrical assemblies. Whether you are a seasoned engineer working on complex industrial systems or a hobbyist bringing your first circuit to life, this 60 40 sn pb wire solder provides the performance, reliability, and value you need to ensure every connection is perfect. Stock up on this classic soldering solution today and experience the difference that quality materials make.