| Availability: | |

|---|---|

| Quantity: | |

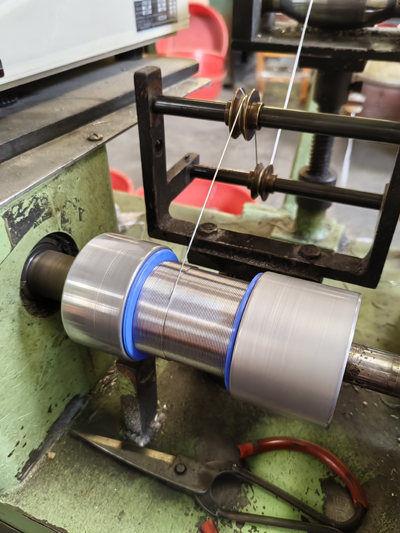

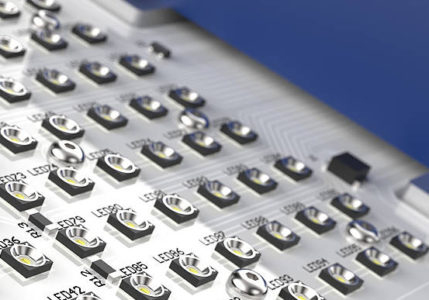

In the precise and demanding world of electronics manufacturing, especially in LED light assembly, the choice of solder is a critical determinant of product quality, reliability, and longevity. Among the various solder alloys available, the Tin Solder Roll 30 70 stands out as a classic and highly reliable option. Specifically, the Tin Solder Roll Sn30 Pb70 formulation—comprising 30% tin and 70% lead—offers a unique set of properties that make it exceptionally suitable for certain types of electronic work. This comprehensive guide delves deep into this specific alloy, exploring its characteristics, the advantages of its various package weights like the Tin Solder Roll Sn30 Pb70 100g to the Tin Solder Roll Sn30 Pb70 1kg, and its optimal application, particularly when paired with a Diameter 0.8mm wire for LED assembly processes.

The designation Tin Solder Roll Sn30 Pb70 clearly defines its metallic composition: 30% Tin (Sn) and 70% Lead (Pb). This eutectic or near-eutectic alloy has a melting point range that is well-suited for manual soldering and certain wave soldering applications. While lead-free solders have become prevalent due to RoHS directives in consumer electronics, Sn30Pb70 remains a staple in applications where its superior mechanical and thermal fatigue properties are paramount, and where exemptions apply, such as in certain automotive, aerospace, and high-reliability industrial electronics—including specific LED applications.

The Tin Solder Roll 30 70 offers several benefits. The higher lead content provides excellent wettability, a smooth solder flow, and reduces the likelihood of solder bridging. It creates very reliable solder joints with good ductility, which is the ability to deform under stress without cracking. This is crucial for assemblies that experience thermal cycling or mechanical stress. Furthermore, it has a lower melting point compared to many lead-free alternatives, which reduces thermal shock on sensitive components like LEDs.

LED light assemblies, from PCB strips to individual bulb components, often involve small, heat-sensitive pads and terminals. Using a solder wire with the correct diameter is essential for control and precision. A Diameter 0.8mm solder wire is arguably the most versatile and commonly used size for such work. It is substantial enough to feed smoothly and carry sufficient flux and solder to form a robust joint, yet fine enough to allow for pinpoint accuracy without over-applying solder. This prevents issues like shorts, cold joints, or damage to the LED due to excessive heat exposure.

The Tin Solder Roll Sn30 Pb70 in 0.8mm diameter provides an optimal balance. For technicians performing hand soldering of LEDs, the wire feeds consistently, melts predictably due to the alloy's properties, and the flux core (typically rosin-based) activates effectively to clean the copper surfaces and ensure a strong, shiny, and reliable connection. This specific combination—the Tin Solder Roll 30 70 alloy with a 0.8mm gauge—is a proven recipe for efficiency and quality in LED manufacturing and repair workstations.

Selecting the right package size for your Tin Solder Roll Sn30 Pb70 is crucial for workflow efficiency, cost management, and solder freshness. Here’s a detailed breakdown of each available weight, highlighting its ideal use case.

The Tin Solder Roll Sn30 Pb70 100g is the compact, portable solution. It is ideal for hobbyists, technicians doing field repairs, or production lines with very low volume usage. Its small size makes it easy to handle and store, minimizing waste if the solder type needs to be changed frequently. For a specialist focusing on occasional LED assembly or repair, this size offers practicality without commitment.

Stepping up, the Tin Solder Roll Sn30 Pb70 200g provides more material for sustained work. It suits small to medium workshops, prototyping labs, or as a backup roll for specific applications on a larger production floor. It balances the need for adequate quantity with the avoidance of solder aging that can sometimes affect very large rolls over extended periods.

Similar to the 200g but with a slight increase, the Tin Solder Roll Sn30 Pb70 250g is a popular weight for serious hobbyists, freelance repair professionals, and low-volume commercial assemblers. It’s a cost-effective size that reduces the frequency of reorders compared to the 100g roll, making it a smart choice for predictable, ongoing projects involving LED assemblies.

For dedicated production benches, the Tin Solder Roll Sn30 Pb70 400g is a significant workhorse. It supports small-batch manufacturing runs of LED lights, signage, or control modules without requiring constant roll changes. This improves productivity and ensures consistency across a production lot. It's also a sensible purchase for businesses looking to buy in moderate bulk for multiple technicians.

The Tin Solder Roll Sn30 Pb70 500g represents the sweet spot for many small to medium-sized enterprises (SMEs). It offers substantial material volume, yielding a lower cost per gram, while still being a manageable physical package that fits on standard soldering stations. A facility with several technicians assembling LED lights daily will find the 500g roll to be an efficient and economical standard issue.

Moving into high-volume territory, the Tin Solder Roll Sn30 Pb70 800g is designed for continuous production environments. This size minimizes downtime for roll changes, ensures alloy consistency across very large batches of products, and offers even greater economies of scale. It is the choice for factories where LED light assembly is a primary and constant activity.

At the top of the range, the Tin Solder Roll Sn30 Pb70 1kg is the industrial-scale solution. It is tailored for large-scale manufacturing plants with automated or highly streamlined manual soldering processes. The 1kg roll maximizes value, reduces packaging waste per unit of solder, and is essential for operations where uninterrupted production flow is critical. Storing and handling these rolls properly is key to maintaining solder quality.

A common point of comparison in soldering is the classic Tin Solder Roll 63 37. This alloy, consisting of 63% tin and 37% lead, is a true eutectic alloy with a single, sharp melting point (183°C). The Tin Solder Roll 63 37 0.8mm is extremely popular for general-purpose electronics because it transitions from solid to liquid almost instantly, reducing the risk of cold joints.

Melting Behavior: Sn63Pb37 has a distinct melting point, while Tin Solder Roll 30 70 has a plastic range where it is neither fully solid nor liquid. This can be an advantage for manual "drag" soldering or applications where a slight "cushion" is desired.

Joint Strength and Ductility: The higher lead content in Tin Solder Roll Sn30 Pb70 generally results in a more ductile joint, better suited for environments with vibration or thermal stress. Sn63Pb37 joints are slightly stronger in tensile strength but less ductile.

Cost: Tin is more expensive than lead. Therefore, the Tin Solder Roll Sn30 Pb70 0.8mm typically has a lower raw material cost than the Tin Solder Roll 63 37 0.8mm.

LED-Specific Choice: For many standard LED assemblies, both can work well. However, if the assembly is part of a larger module subject to wider temperature swings or physical flexing, the fatigue resistance of the Tin Solder Roll 30 70 might be preferred. The choice often comes down to specific process requirements and the technician's preference for the solder's "feel."

Always start with a clean, well-tinned soldering iron tip set to the correct temperature (typically 320°C - 380°C for this alloy). Ensure the LED pads and component leads are clean and free of oxidation. Use the Diameter 0.8mm wire in a controlled manner, applying heat to the joint first, then feeding the solder to the heated area, not the iron tip directly.

LEDs are sensitive to heat. Use a precision tip and work quickly. The excellent flow of Tin Solder Roll Sn30 Pb70 helps achieve a good joint with minimal heat exposure. The joint should be concave, smooth, and shiny—a hallmark of a properly formed connection with this alloy. Avoid excessive solder that could create bridges between closely spaced pads on LED strips.

After soldering, visually inspect each joint under good lighting, preferably with magnification. Look for the characteristic bright finish of a good Sn30Pb70 joint. Check for bridges, insufficient solder, or dull/grainy appearance (indicative of a cold joint). For critical applications, consider electrical testing and mechanical stress testing.

Store Tin Solder Roll Sn30 Pb70 in a cool, dry place in its original packaging to prevent oxidation and contamination of the flux core. For larger rolls like the Tin Solder Roll Sn30 Pb70 1kg, ensure they are stored on a flat surface to avoid deformation. Implementing first-in, first-out (FIFO) inventory management is advisable.

While Tin Solder Roll 30 70 is an exceptional performer, it contains lead, a hazardous substance. It is imperative to use it in a well-ventilated area, wash hands after handling, and avoid ingestion or inhalation of fumes. Always comply with local and international regulations (like RoHS) regarding the use of leaded solder. Its use is often restricted or exempted for specific professional and industrial applications—always verify its acceptability for your intended end-product and market.

The Tin Solder Roll Sn30 Pb70 in its various weights—from the convenient Tin Solder Roll Sn30 Pb70 100g to the industrial Tin Solder Roll Sn30 Pb70 1kg—and in the optimal Diameter 0.8mm, represents a time-tested, high-performance solution for LED light assembly. Its superior ductility, reliable performance, and favorable cost make it a steadfast choice in applications where its use is permitted and its properties are valued over lead-free alternatives.

When selecting, consider your production volume: a hobbyist or repair shop may find the 200g or 250g perfect, while a dedicated assembly line will benefit from the efficiency of the 500g, 800g, or 1kg rolls. By understanding the nuances of the Tin Solder Roll 30 70 alloy and pairing it with the correct diameter and disciplined technique, you can ensure strong, durable, and reliable solder joints that will keep your LED assemblies shining brightly for their entire designed lifespan.

Contact us:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: 008613450770997

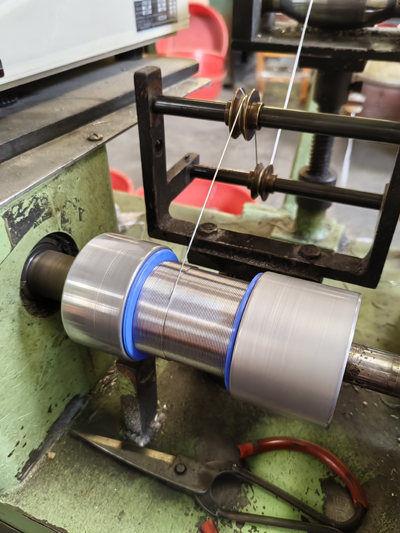

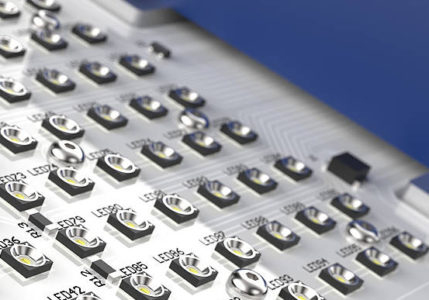

In the precise and demanding world of electronics manufacturing, especially in LED light assembly, the choice of solder is a critical determinant of product quality, reliability, and longevity. Among the various solder alloys available, the Tin Solder Roll 30 70 stands out as a classic and highly reliable option. Specifically, the Tin Solder Roll Sn30 Pb70 formulation—comprising 30% tin and 70% lead—offers a unique set of properties that make it exceptionally suitable for certain types of electronic work. This comprehensive guide delves deep into this specific alloy, exploring its characteristics, the advantages of its various package weights like the Tin Solder Roll Sn30 Pb70 100g to the Tin Solder Roll Sn30 Pb70 1kg, and its optimal application, particularly when paired with a Diameter 0.8mm wire for LED assembly processes.

The designation Tin Solder Roll Sn30 Pb70 clearly defines its metallic composition: 30% Tin (Sn) and 70% Lead (Pb). This eutectic or near-eutectic alloy has a melting point range that is well-suited for manual soldering and certain wave soldering applications. While lead-free solders have become prevalent due to RoHS directives in consumer electronics, Sn30Pb70 remains a staple in applications where its superior mechanical and thermal fatigue properties are paramount, and where exemptions apply, such as in certain automotive, aerospace, and high-reliability industrial electronics—including specific LED applications.

The Tin Solder Roll 30 70 offers several benefits. The higher lead content provides excellent wettability, a smooth solder flow, and reduces the likelihood of solder bridging. It creates very reliable solder joints with good ductility, which is the ability to deform under stress without cracking. This is crucial for assemblies that experience thermal cycling or mechanical stress. Furthermore, it has a lower melting point compared to many lead-free alternatives, which reduces thermal shock on sensitive components like LEDs.

LED light assemblies, from PCB strips to individual bulb components, often involve small, heat-sensitive pads and terminals. Using a solder wire with the correct diameter is essential for control and precision. A Diameter 0.8mm solder wire is arguably the most versatile and commonly used size for such work. It is substantial enough to feed smoothly and carry sufficient flux and solder to form a robust joint, yet fine enough to allow for pinpoint accuracy without over-applying solder. This prevents issues like shorts, cold joints, or damage to the LED due to excessive heat exposure.

The Tin Solder Roll Sn30 Pb70 in 0.8mm diameter provides an optimal balance. For technicians performing hand soldering of LEDs, the wire feeds consistently, melts predictably due to the alloy's properties, and the flux core (typically rosin-based) activates effectively to clean the copper surfaces and ensure a strong, shiny, and reliable connection. This specific combination—the Tin Solder Roll 30 70 alloy with a 0.8mm gauge—is a proven recipe for efficiency and quality in LED manufacturing and repair workstations.

Selecting the right package size for your Tin Solder Roll Sn30 Pb70 is crucial for workflow efficiency, cost management, and solder freshness. Here’s a detailed breakdown of each available weight, highlighting its ideal use case.

The Tin Solder Roll Sn30 Pb70 100g is the compact, portable solution. It is ideal for hobbyists, technicians doing field repairs, or production lines with very low volume usage. Its small size makes it easy to handle and store, minimizing waste if the solder type needs to be changed frequently. For a specialist focusing on occasional LED assembly or repair, this size offers practicality without commitment.

Stepping up, the Tin Solder Roll Sn30 Pb70 200g provides more material for sustained work. It suits small to medium workshops, prototyping labs, or as a backup roll for specific applications on a larger production floor. It balances the need for adequate quantity with the avoidance of solder aging that can sometimes affect very large rolls over extended periods.

Similar to the 200g but with a slight increase, the Tin Solder Roll Sn30 Pb70 250g is a popular weight for serious hobbyists, freelance repair professionals, and low-volume commercial assemblers. It’s a cost-effective size that reduces the frequency of reorders compared to the 100g roll, making it a smart choice for predictable, ongoing projects involving LED assemblies.

For dedicated production benches, the Tin Solder Roll Sn30 Pb70 400g is a significant workhorse. It supports small-batch manufacturing runs of LED lights, signage, or control modules without requiring constant roll changes. This improves productivity and ensures consistency across a production lot. It's also a sensible purchase for businesses looking to buy in moderate bulk for multiple technicians.

The Tin Solder Roll Sn30 Pb70 500g represents the sweet spot for many small to medium-sized enterprises (SMEs). It offers substantial material volume, yielding a lower cost per gram, while still being a manageable physical package that fits on standard soldering stations. A facility with several technicians assembling LED lights daily will find the 500g roll to be an efficient and economical standard issue.

Moving into high-volume territory, the Tin Solder Roll Sn30 Pb70 800g is designed for continuous production environments. This size minimizes downtime for roll changes, ensures alloy consistency across very large batches of products, and offers even greater economies of scale. It is the choice for factories where LED light assembly is a primary and constant activity.

At the top of the range, the Tin Solder Roll Sn30 Pb70 1kg is the industrial-scale solution. It is tailored for large-scale manufacturing plants with automated or highly streamlined manual soldering processes. The 1kg roll maximizes value, reduces packaging waste per unit of solder, and is essential for operations where uninterrupted production flow is critical. Storing and handling these rolls properly is key to maintaining solder quality.

A common point of comparison in soldering is the classic Tin Solder Roll 63 37. This alloy, consisting of 63% tin and 37% lead, is a true eutectic alloy with a single, sharp melting point (183°C). The Tin Solder Roll 63 37 0.8mm is extremely popular for general-purpose electronics because it transitions from solid to liquid almost instantly, reducing the risk of cold joints.

Melting Behavior: Sn63Pb37 has a distinct melting point, while Tin Solder Roll 30 70 has a plastic range where it is neither fully solid nor liquid. This can be an advantage for manual "drag" soldering or applications where a slight "cushion" is desired.

Joint Strength and Ductility: The higher lead content in Tin Solder Roll Sn30 Pb70 generally results in a more ductile joint, better suited for environments with vibration or thermal stress. Sn63Pb37 joints are slightly stronger in tensile strength but less ductile.

Cost: Tin is more expensive than lead. Therefore, the Tin Solder Roll Sn30 Pb70 0.8mm typically has a lower raw material cost than the Tin Solder Roll 63 37 0.8mm.

LED-Specific Choice: For many standard LED assemblies, both can work well. However, if the assembly is part of a larger module subject to wider temperature swings or physical flexing, the fatigue resistance of the Tin Solder Roll 30 70 might be preferred. The choice often comes down to specific process requirements and the technician's preference for the solder's "feel."

Always start with a clean, well-tinned soldering iron tip set to the correct temperature (typically 320°C - 380°C for this alloy). Ensure the LED pads and component leads are clean and free of oxidation. Use the Diameter 0.8mm wire in a controlled manner, applying heat to the joint first, then feeding the solder to the heated area, not the iron tip directly.

LEDs are sensitive to heat. Use a precision tip and work quickly. The excellent flow of Tin Solder Roll Sn30 Pb70 helps achieve a good joint with minimal heat exposure. The joint should be concave, smooth, and shiny—a hallmark of a properly formed connection with this alloy. Avoid excessive solder that could create bridges between closely spaced pads on LED strips.

After soldering, visually inspect each joint under good lighting, preferably with magnification. Look for the characteristic bright finish of a good Sn30Pb70 joint. Check for bridges, insufficient solder, or dull/grainy appearance (indicative of a cold joint). For critical applications, consider electrical testing and mechanical stress testing.

Store Tin Solder Roll Sn30 Pb70 in a cool, dry place in its original packaging to prevent oxidation and contamination of the flux core. For larger rolls like the Tin Solder Roll Sn30 Pb70 1kg, ensure they are stored on a flat surface to avoid deformation. Implementing first-in, first-out (FIFO) inventory management is advisable.

While Tin Solder Roll 30 70 is an exceptional performer, it contains lead, a hazardous substance. It is imperative to use it in a well-ventilated area, wash hands after handling, and avoid ingestion or inhalation of fumes. Always comply with local and international regulations (like RoHS) regarding the use of leaded solder. Its use is often restricted or exempted for specific professional and industrial applications—always verify its acceptability for your intended end-product and market.

The Tin Solder Roll Sn30 Pb70 in its various weights—from the convenient Tin Solder Roll Sn30 Pb70 100g to the industrial Tin Solder Roll Sn30 Pb70 1kg—and in the optimal Diameter 0.8mm, represents a time-tested, high-performance solution for LED light assembly. Its superior ductility, reliable performance, and favorable cost make it a steadfast choice in applications where its use is permitted and its properties are valued over lead-free alternatives.

When selecting, consider your production volume: a hobbyist or repair shop may find the 200g or 250g perfect, while a dedicated assembly line will benefit from the efficiency of the 500g, 800g, or 1kg rolls. By understanding the nuances of the Tin Solder Roll 30 70 alloy and pairing it with the correct diameter and disciplined technique, you can ensure strong, durable, and reliable solder joints that will keep your LED assemblies shining brightly for their entire designed lifespan.

Contact us:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: 008613450770997

The selection of solder is a foundational element in the successful assembly and repair of LED lighting systems. The eutectic 63 37 sn pb solder offers an unparalleled combination of a low melting point, excellent wettability, and joint reliability that is perfectly suited to the thermal sensitivity of LED components. By understanding the specific applications for each diameter—from the precision of 63 37 sn pb solder 1.0mm to the power of 63 37 sn pb solder 2.0mm—you can dramatically improve the quality and efficiency of your work. Packaging this superior alloy as solder in a reel, specifically in a 63 37 sn pb solder 1 kg reel, adds layers of practicality, economy, and consistency that benefit everyone from the professional production engineer to the meticulous hobbyist. Therefore, equipping your workspace with the appropriate diameter of 63 37 sn pb solder for LED Lights is not just a purchase; it is an investment in achieving superior, reliable, and professional results in all you

Our comprehensive range of 63 37 leaded wire solder for electronics is meticulously designed to meet the exacting demands of modern electronics work. The eutectic 63/37 tin-lead alloy guarantees reliable, shiny joints free from cold solder defects. The availability of both 63 37 leaded solder 0.6mm for precision tasks and 63 37 leaded solder 0.9mm for versatile general-purpose work ensures you have the right tool for every job. Furthermore, our flexible packaging—from the bulk 63 37 leaded solder 454g for professionals, to the standard 63 37 leaded solder 227g, and the accessible 63 37 leaded solder 100g for beginners—means there is a perfect option for every user and budget. Elevate your soldering work with the proven performance and quality of genuine 63 37 leaded solder.

Welcome to XF Solder, a leading manufacturer from China dedicated to producing high-quality soldering materials for the global market. We specialize in creating reliable, consistent, and performance-driven solder products that meet the rigorous demands of various industries. Our flagship product, the 60 40 Solder .032'' 1 lb spool, represents the gold standard in through-hole and general-purpose electronics assembly. This article provides a detailed overview of why this specific formulation and packaging is an indispensable inventory item for distributors, a superior choice for importers seeking quality from China, and a perfect 60 40 Solder 1 lb for Wholesale operations globally. We will explore its technical specifications, unparalleled benefits, and the strategic advantage it offers in the competitive electronics supply chain.

The combination of the proven 60 sn 40 pb alloy, the convenience of three standard diameters (1.6mm, 1.8mm, 2mm), and the economic 1lb (454g) packaging makes this product an indispensable tool for anyone involved in creating or repairing electrical assemblies. Whether you are a seasoned engineer working on complex industrial systems or a hobbyist bringing your first circuit to life, this 60 40 sn pb wire solder provides the performance, reliability, and value you need to ensure every connection is perfect. Stock up on this classic soldering solution today and experience the difference that quality materials make.