| Availability: | |

|---|---|

| Quantity: | |

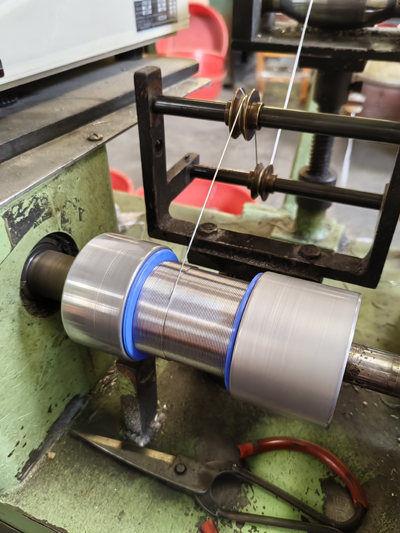

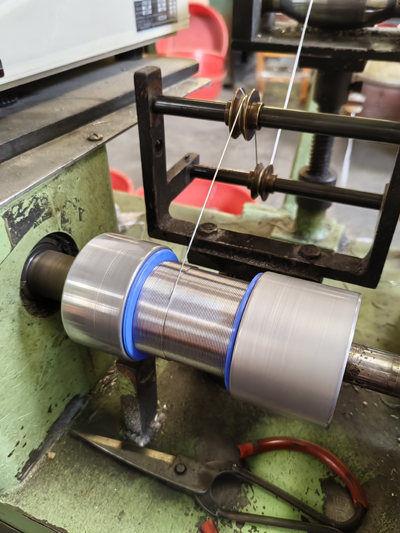

In the world of electronics, metalwork, and DIY repairs, the quality of your solder can make the difference between a durable connection and a failed joint. Among the various solder types available, one stands out for its reliability and versatility in general-purpose applications: the roll of tin thread 60 40. Specifically, the tin thread Sn60 Pb40 alloy, available in convenient weights like tin thread 100g, tin thread 200g, tin thread 500g, and tin thread 1kg, is a cornerstone material for professionals and hobbyists alike. This comprehensive guide delves deep into the characteristics, applications, and benefits of using this specific solder alloy. Whether you are performing delicate electronic repairs or more robust metal joins, understanding the properties of this thread of tin is crucial for achieving strong, conductive, and reliable solder joints every time.

The term tin thread 60 40 refers to a solder alloy composed of 60% tin (Sn) and 40% lead (Pb). This specific ratio is not arbitrary; it represents the eutectic point for the tin-lead system. A eutectic alloy has a single, sharp melting point rather than a melting range. For Sn60 Pb40, this melting point is approximately 188°C (370°F). This is a critical property because it means the solder transitions rapidly from a solid to a liquid state and back again as it cools, minimizing the time the components are exposed to heat and reducing the risk of cold solder joints. When you purchase a roll of tin thread, you are getting this predictable and manageable material in a user-friendly form factor.

The tin thread made from this alloy offers an excellent balance of properties. It provides good tensile strength and shear strength, creating joints that can withstand mechanical stress and vibration. The solder flows smoothly due to its low surface tension in the molten state, ensuring it wets the surfaces of the metals being joined effectively. This wetting action is essential for creating a solid metallurgical bond rather than just a mechanical adhesion. Furthermore, the roll of tin 60 40 produces bright, shiny joints when cooled properly, which is often a visual indicator of a good solder connection. Its electrical conductivity is sufficient for most electronic applications, ensuring minimal signal loss or voltage drop across the connection.

The primary advantage of the tin thread Sn60 Pb40 is its eutectic nature. For the technician or maker, this translates to easier work. There’s no "pasty" or plastic phase where the solder is partially melted. It goes from solid to liquid almost instantly, allowing for cleaner application and immediate release of the soldering iron tip. This characteristic is particularly beneficial for hand soldering, where control is paramount. A roll of tin thread designed with this alloy minimizes bridging (unwanted connections between adjacent pins or pads) and produces consistent results across multiple joints.

This alloy has been the industry standard for decades for general soldering outside of specific food-safe or potable water applications. The reliability of a joint made with tin thread 60 40 is well-documented. It creates ductile joints that are less prone to cracking under thermal cycling compared to some lead-free alternatives. For repairing legacy electronics, vintage audio equipment, or any application where long-term reliability under varying conditions is needed, a roll of tin 60 40 remains an excellent choice. Its performance is predictable, and troubleshooting faulty joints is often more straightforward.

Compared to many specialized or high-silver-content solders, standard tin thread made from Sn60/Pb40 is relatively inexpensive. This makes it an economical choice for high-volume work, educational settings, or hobbyists who solder frequently. Its versatility is another major strength. The same roll of tin thread can be used for through-hole PCB assembly, point-to-point wiring, stained glass work, light plumbing on non-potable systems, and radiator repairs. This "one-spool-does-many-jobs" aspect simplifies inventory and is ideal for general workshop use.

For infrequent users, hobbyists starting out, or technicians who need a small amount for specific, delicate tasks, the tin thread 100g roll is perfect. It's compact, easy to handle, and minimizes waste if you have a limited number of joints to make. This size is excellent for detailed work like repairing small electronic components, jewelry making, or model building where precision is key. A small roll of tin thread in this weight is also highly portable, fitting easily into a compact toolkit for on-the-go repairs.

Stepping up, the tin thread 200g roll offers a great balance between quantity and manageability. It is substantial enough for a moderate-sized project, such as assembling a single complex circuit board or completing several smaller repair jobs, without the spool being overly large or heavy. For an electronics enthusiast who undertakes weekend projects or a maintenance technician who performs regular equipment repairs, the tin thread 200g weight provides a practical supply that will last for multiple sessions without taking up excessive space in the workspace.

For the serious hobbyist, small-scale manufacturer, or repair shop, the tin thread 500g roll is often the workhorse size. It represents a significant amount of material, reducing the frequency of reordering and often coming at a better price per gram than the smaller spools. This size is ideal if you are consistently building kits, refurbishing electronics, or engaged in crafting that requires substantial soldering, like creating stained-glass panels. The roll of tin thread in 500g ensures you rarely run out mid-project and is a cost-effective choice for sustained activity.

At the top of the common weight range is the tin thread 1kg roll. This is the choice for professional environments, small production lines, educational institutions with multiple workstations, or very dedicated hobbyists with high consumption. Purchasing a tin thread 1kg spool offers the greatest economy of scale. It is the most efficient option for anyone for whom soldering is a core part of their workflow. Storing a roll of tin 60 40 of this size requires a bit more consideration, but the payoff is a long-lasting, readily available supply of high-quality solder.

This is the most common application for tin thread 60 40. It is used to solder components onto printed circuit boards (PCBs), create connections between wires, and attach connectors or terminals. Its reliable wetting action and strong bond make it suitable for everything from consumer electronics to industrial control boards. A roll of tin thread is a staple on every electronics workbench.

For general electrical work that does not involve high temperatures or specific code restrictions against lead-based solder, tin thread Sn60 Pb40 is excellent for joining copper wires, tinning wire ends to prevent fraying, and securing connections in junction boxes or terminals. Its good conductivity ensures efficient current flow.

In stained glass art, the solder is used to join the lead came or copper foil between glass pieces. The tin thread 60 40 is a traditional choice here for its beauty and workability. Similarly, in jewelry making and model engineering (such as for model railways or ships), this solder is used for its strength and ability to create clean, fine joints on small metal parts.

Important Note: Lead-based solder should NEVER be used for joints in pipes carrying drinking water (potable water) due to the risk of lead contamination. However, for closed heating systems, automotive radiators, or decorative plumbing, a roll of tin 60 40 can provide a strong, leak-proof seal on copper pipes and fittings.

To get the best results from your tin thread, correct technique is essential. Ensure the surfaces to be joined are clean and free of oxidation. Use a suitable flux—often, the solder has a flux core, but additional flux may be needed for larger or dirtier joints. Apply the tip of the soldering iron to heat both the component lead and the pad/wire simultaneously. Then, feed the thread of tin into the heated junction, not directly onto the iron tip. The solder should flow smoothly and evenly, coating the surfaces. Remove the heat and allow the joint to cool undisturbed, forming the characteristic shiny finish.

While tin thread Sn60 Pb40 is safe to use with proper precautions, awareness is key. Always work in a well-ventilated area, as soldering fumes from the flux can be irritating. A fume extractor is highly recommended. Wash your hands after handling solder, especially before eating, to avoid incidental ingestion of lead. Wear safety glasses to protect against splashes. Proper storage of your roll of tin thread is also important—keep it in a dry place and clearly labeled, away from children and pets.

To maintain the quality of your tin thread, store the spool in its original container or a sealed bag to prevent oxidation and contamination. A tarnished or dirty solder surface can impair its flow and wetting capabilities. For the larger tin thread 1kg spools, consider using a dispenser or holder that allows the solder to feed smoothly without tangling or kinking. Always cut or break off the amount you need cleanly to avoid deforming the remaining thread of tin on the spool.

The rise of environmental regulations, notably the Restriction of Hazardous Substances (RoHS) directive, has made lead-free solders the mandatory standard in commercial electronics manufacturing. Common lead-free alloys, like SAC305 (Tin-Silver-Copper), have higher melting points (around 217-220°C) and can be slightly less forgiving in terms of wetting and joint appearance. The roll of tin 60 40, by comparison, offers a lower working temperature, better wetting on a wider variety of surfaces, and often produces more aesthetically pleasing joints with less effort. For non-commercial, repair, or hobby work where RoHS compliance is not required, many practitioners still prefer the performance of tin thread Sn60 Pb40.

Your choice depends on the application. For repairing or building equipment that must be RoHS compliant, you must use a certified lead-free solder. However, for personal projects, vintage electronics repair, stained glass, or general non-electronic uses, the tin thread 60 40 offers unparalleled ease of use and proven reliability. Having a roll of tin thread of each type might be the ideal solution for a versatile workshop.

In conclusion, the roll of tin thread 60 40 Sn60 Pb40 remains an indispensable material for a vast array of soldering tasks. Its optimal eutectic composition, excellent workability, and strong, reliable joints justify its continued popularity. By selecting the appropriate weight—whether it's the convenient tin thread 100g for small jobs, the versatile tin thread 500g for regular projects, or the economical tin thread 1kg for high-volume work—you equip yourself with a fundamental tool for creation and repair. Understanding the properties and best practices for using this thread of tin empowers you to achieve professional results, ensuring your electrical connections are solid, your crafts are beautiful, and your repairs stand the test of time. For general soldering, the roll of tin 60 40 is a classic choice that continues to deliver exceptional value and performance.

Contact us:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: 008613450770997

In the world of electronics, metalwork, and DIY repairs, the quality of your solder can make the difference between a durable connection and a failed joint. Among the various solder types available, one stands out for its reliability and versatility in general-purpose applications: the roll of tin thread 60 40. Specifically, the tin thread Sn60 Pb40 alloy, available in convenient weights like tin thread 100g, tin thread 200g, tin thread 500g, and tin thread 1kg, is a cornerstone material for professionals and hobbyists alike. This comprehensive guide delves deep into the characteristics, applications, and benefits of using this specific solder alloy. Whether you are performing delicate electronic repairs or more robust metal joins, understanding the properties of this thread of tin is crucial for achieving strong, conductive, and reliable solder joints every time.

The term tin thread 60 40 refers to a solder alloy composed of 60% tin (Sn) and 40% lead (Pb). This specific ratio is not arbitrary; it represents the eutectic point for the tin-lead system. A eutectic alloy has a single, sharp melting point rather than a melting range. For Sn60 Pb40, this melting point is approximately 188°C (370°F). This is a critical property because it means the solder transitions rapidly from a solid to a liquid state and back again as it cools, minimizing the time the components are exposed to heat and reducing the risk of cold solder joints. When you purchase a roll of tin thread, you are getting this predictable and manageable material in a user-friendly form factor.

The tin thread made from this alloy offers an excellent balance of properties. It provides good tensile strength and shear strength, creating joints that can withstand mechanical stress and vibration. The solder flows smoothly due to its low surface tension in the molten state, ensuring it wets the surfaces of the metals being joined effectively. This wetting action is essential for creating a solid metallurgical bond rather than just a mechanical adhesion. Furthermore, the roll of tin 60 40 produces bright, shiny joints when cooled properly, which is often a visual indicator of a good solder connection. Its electrical conductivity is sufficient for most electronic applications, ensuring minimal signal loss or voltage drop across the connection.

The primary advantage of the tin thread Sn60 Pb40 is its eutectic nature. For the technician or maker, this translates to easier work. There’s no "pasty" or plastic phase where the solder is partially melted. It goes from solid to liquid almost instantly, allowing for cleaner application and immediate release of the soldering iron tip. This characteristic is particularly beneficial for hand soldering, where control is paramount. A roll of tin thread designed with this alloy minimizes bridging (unwanted connections between adjacent pins or pads) and produces consistent results across multiple joints.

This alloy has been the industry standard for decades for general soldering outside of specific food-safe or potable water applications. The reliability of a joint made with tin thread 60 40 is well-documented. It creates ductile joints that are less prone to cracking under thermal cycling compared to some lead-free alternatives. For repairing legacy electronics, vintage audio equipment, or any application where long-term reliability under varying conditions is needed, a roll of tin 60 40 remains an excellent choice. Its performance is predictable, and troubleshooting faulty joints is often more straightforward.

Compared to many specialized or high-silver-content solders, standard tin thread made from Sn60/Pb40 is relatively inexpensive. This makes it an economical choice for high-volume work, educational settings, or hobbyists who solder frequently. Its versatility is another major strength. The same roll of tin thread can be used for through-hole PCB assembly, point-to-point wiring, stained glass work, light plumbing on non-potable systems, and radiator repairs. This "one-spool-does-many-jobs" aspect simplifies inventory and is ideal for general workshop use.

For infrequent users, hobbyists starting out, or technicians who need a small amount for specific, delicate tasks, the tin thread 100g roll is perfect. It's compact, easy to handle, and minimizes waste if you have a limited number of joints to make. This size is excellent for detailed work like repairing small electronic components, jewelry making, or model building where precision is key. A small roll of tin thread in this weight is also highly portable, fitting easily into a compact toolkit for on-the-go repairs.

Stepping up, the tin thread 200g roll offers a great balance between quantity and manageability. It is substantial enough for a moderate-sized project, such as assembling a single complex circuit board or completing several smaller repair jobs, without the spool being overly large or heavy. For an electronics enthusiast who undertakes weekend projects or a maintenance technician who performs regular equipment repairs, the tin thread 200g weight provides a practical supply that will last for multiple sessions without taking up excessive space in the workspace.

For the serious hobbyist, small-scale manufacturer, or repair shop, the tin thread 500g roll is often the workhorse size. It represents a significant amount of material, reducing the frequency of reordering and often coming at a better price per gram than the smaller spools. This size is ideal if you are consistently building kits, refurbishing electronics, or engaged in crafting that requires substantial soldering, like creating stained-glass panels. The roll of tin thread in 500g ensures you rarely run out mid-project and is a cost-effective choice for sustained activity.

At the top of the common weight range is the tin thread 1kg roll. This is the choice for professional environments, small production lines, educational institutions with multiple workstations, or very dedicated hobbyists with high consumption. Purchasing a tin thread 1kg spool offers the greatest economy of scale. It is the most efficient option for anyone for whom soldering is a core part of their workflow. Storing a roll of tin 60 40 of this size requires a bit more consideration, but the payoff is a long-lasting, readily available supply of high-quality solder.

This is the most common application for tin thread 60 40. It is used to solder components onto printed circuit boards (PCBs), create connections between wires, and attach connectors or terminals. Its reliable wetting action and strong bond make it suitable for everything from consumer electronics to industrial control boards. A roll of tin thread is a staple on every electronics workbench.

For general electrical work that does not involve high temperatures or specific code restrictions against lead-based solder, tin thread Sn60 Pb40 is excellent for joining copper wires, tinning wire ends to prevent fraying, and securing connections in junction boxes or terminals. Its good conductivity ensures efficient current flow.

In stained glass art, the solder is used to join the lead came or copper foil between glass pieces. The tin thread 60 40 is a traditional choice here for its beauty and workability. Similarly, in jewelry making and model engineering (such as for model railways or ships), this solder is used for its strength and ability to create clean, fine joints on small metal parts.

Important Note: Lead-based solder should NEVER be used for joints in pipes carrying drinking water (potable water) due to the risk of lead contamination. However, for closed heating systems, automotive radiators, or decorative plumbing, a roll of tin 60 40 can provide a strong, leak-proof seal on copper pipes and fittings.

To get the best results from your tin thread, correct technique is essential. Ensure the surfaces to be joined are clean and free of oxidation. Use a suitable flux—often, the solder has a flux core, but additional flux may be needed for larger or dirtier joints. Apply the tip of the soldering iron to heat both the component lead and the pad/wire simultaneously. Then, feed the thread of tin into the heated junction, not directly onto the iron tip. The solder should flow smoothly and evenly, coating the surfaces. Remove the heat and allow the joint to cool undisturbed, forming the characteristic shiny finish.

While tin thread Sn60 Pb40 is safe to use with proper precautions, awareness is key. Always work in a well-ventilated area, as soldering fumes from the flux can be irritating. A fume extractor is highly recommended. Wash your hands after handling solder, especially before eating, to avoid incidental ingestion of lead. Wear safety glasses to protect against splashes. Proper storage of your roll of tin thread is also important—keep it in a dry place and clearly labeled, away from children and pets.

To maintain the quality of your tin thread, store the spool in its original container or a sealed bag to prevent oxidation and contamination. A tarnished or dirty solder surface can impair its flow and wetting capabilities. For the larger tin thread 1kg spools, consider using a dispenser or holder that allows the solder to feed smoothly without tangling or kinking. Always cut or break off the amount you need cleanly to avoid deforming the remaining thread of tin on the spool.

The rise of environmental regulations, notably the Restriction of Hazardous Substances (RoHS) directive, has made lead-free solders the mandatory standard in commercial electronics manufacturing. Common lead-free alloys, like SAC305 (Tin-Silver-Copper), have higher melting points (around 217-220°C) and can be slightly less forgiving in terms of wetting and joint appearance. The roll of tin 60 40, by comparison, offers a lower working temperature, better wetting on a wider variety of surfaces, and often produces more aesthetically pleasing joints with less effort. For non-commercial, repair, or hobby work where RoHS compliance is not required, many practitioners still prefer the performance of tin thread Sn60 Pb40.

Your choice depends on the application. For repairing or building equipment that must be RoHS compliant, you must use a certified lead-free solder. However, for personal projects, vintage electronics repair, stained glass, or general non-electronic uses, the tin thread 60 40 offers unparalleled ease of use and proven reliability. Having a roll of tin thread of each type might be the ideal solution for a versatile workshop.

In conclusion, the roll of tin thread 60 40 Sn60 Pb40 remains an indispensable material for a vast array of soldering tasks. Its optimal eutectic composition, excellent workability, and strong, reliable joints justify its continued popularity. By selecting the appropriate weight—whether it's the convenient tin thread 100g for small jobs, the versatile tin thread 500g for regular projects, or the economical tin thread 1kg for high-volume work—you equip yourself with a fundamental tool for creation and repair. Understanding the properties and best practices for using this thread of tin empowers you to achieve professional results, ensuring your electrical connections are solid, your crafts are beautiful, and your repairs stand the test of time. For general soldering, the roll of tin 60 40 is a classic choice that continues to deliver exceptional value and performance.

Contact us:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: 008613450770997

The selection of solder is a foundational element in the successful assembly and repair of LED lighting systems. The eutectic 63 37 sn pb solder offers an unparalleled combination of a low melting point, excellent wettability, and joint reliability that is perfectly suited to the thermal sensitivity of LED components. By understanding the specific applications for each diameter—from the precision of 63 37 sn pb solder 1.0mm to the power of 63 37 sn pb solder 2.0mm—you can dramatically improve the quality and efficiency of your work. Packaging this superior alloy as solder in a reel, specifically in a 63 37 sn pb solder 1 kg reel, adds layers of practicality, economy, and consistency that benefit everyone from the professional production engineer to the meticulous hobbyist. Therefore, equipping your workspace with the appropriate diameter of 63 37 sn pb solder for LED Lights is not just a purchase; it is an investment in achieving superior, reliable, and professional results in all you

Our comprehensive range of 63 37 leaded wire solder for electronics is meticulously designed to meet the exacting demands of modern electronics work. The eutectic 63/37 tin-lead alloy guarantees reliable, shiny joints free from cold solder defects. The availability of both 63 37 leaded solder 0.6mm for precision tasks and 63 37 leaded solder 0.9mm for versatile general-purpose work ensures you have the right tool for every job. Furthermore, our flexible packaging—from the bulk 63 37 leaded solder 454g for professionals, to the standard 63 37 leaded solder 227g, and the accessible 63 37 leaded solder 100g for beginners—means there is a perfect option for every user and budget. Elevate your soldering work with the proven performance and quality of genuine 63 37 leaded solder.

Welcome to XF Solder, a leading manufacturer from China dedicated to producing high-quality soldering materials for the global market. We specialize in creating reliable, consistent, and performance-driven solder products that meet the rigorous demands of various industries. Our flagship product, the 60 40 Solder .032'' 1 lb spool, represents the gold standard in through-hole and general-purpose electronics assembly. This article provides a detailed overview of why this specific formulation and packaging is an indispensable inventory item for distributors, a superior choice for importers seeking quality from China, and a perfect 60 40 Solder 1 lb for Wholesale operations globally. We will explore its technical specifications, unparalleled benefits, and the strategic advantage it offers in the competitive electronics supply chain.

The combination of the proven 60 sn 40 pb alloy, the convenience of three standard diameters (1.6mm, 1.8mm, 2mm), and the economic 1lb (454g) packaging makes this product an indispensable tool for anyone involved in creating or repairing electrical assemblies. Whether you are a seasoned engineer working on complex industrial systems or a hobbyist bringing your first circuit to life, this 60 40 sn pb wire solder provides the performance, reliability, and value you need to ensure every connection is perfect. Stock up on this classic soldering solution today and experience the difference that quality materials make.