| Availability: | |

|---|---|

| Quantity: | |

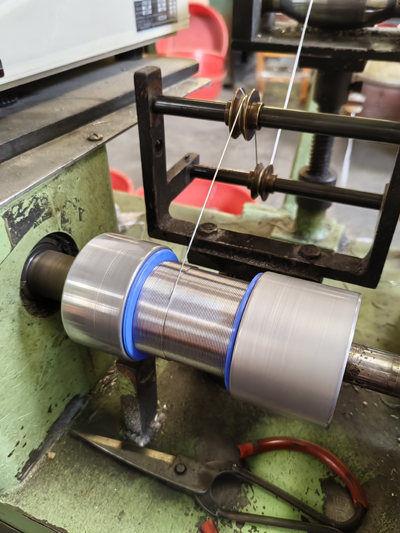

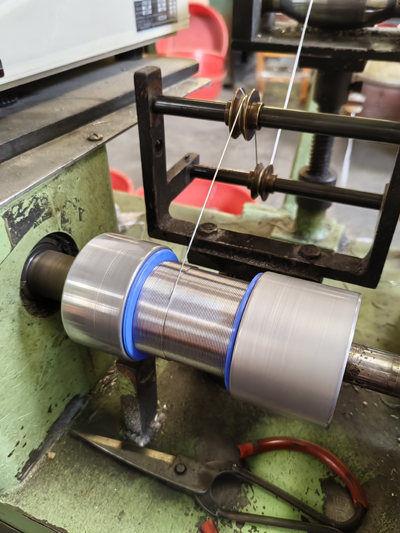

In the demanding world of electronics manufacturing and repair, balancing cost with performance is a constant challenge. Enter Tin Wire Sn15 Pb85, a robust and economical solder alloy that delivers dependable results without straining your budget. This comprehensive guide explores the specifics of this 15% tin and 85% lead composition wire, particularly in the popular 0.8mm diameter, available in versatile reel weights from 100g to 1000g. Designed for general circuit board soldering, this alloy presents a compelling alternative to more expensive options like Sn60Pb40, making it ideal for factory production lines and repair workshops where volume and value are paramount. While its performance is distinct from high-tin alloys, its "good enough" welding quality for many applications, combined with its cheap price, positions Tin Wire 15 85 as a smart choice for bulk soldering operations and routine electrical repairs.

Tin Wire Sn15 Pb85 is a solder alloy composed of 15% tin (Sn) and 85% lead (Pb). This eutectic-like alloy has a melting point range that is higher than standard tin-lead eutectic (Sn63Pb37 or Sn60Pb40), typically beginning around 183°C (361°F) and becoming fully molten at a higher temperature. This specific ratio prioritizes cost savings—since tin is more expensive than lead—while retaining sufficient tin content to create a metallic bond with copper surfaces on circuit boards. The Tin Wire 15 85 formulation offers excellent wettability for general purposes, producing reliable solder joints with good mechanical strength for applications that do not require lead-free compliance. Its characteristics make the Tin Wire Sn15 Pb85 for Circuit Board work a practical reality for countless projects, especially when used with appropriate fluxes and techniques.

The diameter of solder wire is crucial for controlled application and efficient consumption. The Tin Wire 15 85 0.8mm variant strikes an ideal balance for a wide range of general soldering tasks. This 0.8mm diameter is substantial enough to allow for rapid deposition of solder, speeding up work in high-volume environments like factory assembly lines. Simultaneously, it is fine enough to permit reasonable control for through-hole component soldering, larger surface-mount pads, and general repair work on circuit boards. The Tin Wire Sn15 Pb85 0.8mm provides a smooth feed from the reel, minimizes waste, and is compatible with most standard soldering irons and automated dispensers. Its versatility across different reel sizes, from the compact Tin Wire Sn15 Pb85 100g 0.8mm to the bulk Tin Wire Sn15 Pb85 1000g 0.8mm, means one diameter can often suffice for multiple soldering stations within a facility.

Flexibility in packaging is key for operational efficiency. Tin Wire Sn15 Pb85 is thoughtfully offered in a range of reel weights to match different usage scales, all featuring the practical 0.8mm diameter.

Tin Wire Sn15 Pb85 100g 0.8mm: The perfect starter or trial size. This compact reel is excellent for repair technicians, hobbyists, or for low-volume tasks where portability is important. It allows users to test the performance of Tin Wire 15 85 without a large upfront investment.

Tin Wire Sn15 Pb85 400g 0.8mm & Tin Wire Sn15 Pb85 500g 0.8mm: These mid-range sizes are workhorses for busy repair shops and small to medium batch production. The Tin Wire Sn15 Pb85 500g 0.8mm reel offers a great balance between capacity and manageability, reducing the frequency of reel changes compared to the 100g size.

Tin Wire Sn15 Pb85 800g 0.8mm & Tin Wire Sn15 Pb85 1000g 0.8mm: These are the bulk industrial choices. The Tin Wire Sn15 Pb85 1000g 0.8mm reel maximizes value for high-throughput factory environments. It minimizes downtime for reloading and offers the lowest cost per gram, directly supporting the core advantage of a cheap price for bulk soldering operations on general circuit boards.

A primary reason for the popularity of Tin Wire Sn15 Pb85 is its significant cost advantage over the more common Solder Wire Sn60Pb40 alloy. This section breaks down the key differences.

Cost Savings: The higher lead content in Tin Wire 15 85 makes it substantially less expensive. For operations that go through kilograms of solder weekly, this translates to direct and considerable reductions in consumable costs.

Performance Considerations: Sn60Pb40 is a eutectic alloy with a sharp melting point (around 183°C), excellent flow, and strong, shiny joints. Tin Wire Sn15 Pb85 has a plastic range during melting, which can require slightly different technique. Its joints may appear duller and have lower tensile strength than Sn60Pb40. However, for many general circuit board soldering applications—such as through-hole components, wire terminations, and large tabs—the mechanical and electrical performance of Tin Wire Sn15 Pb85 is entirely adequate ("good enough"). The key is matching the alloy to the application's demands.

Best Use Cases: Choose Sn60Pb40 for fine-pitch SMD work, high-reliability military/aerospace applications, or where superior joint aesthetics are required. Choose Tin Wire Sn15 Pb85 for Circuit Board soldering in cost-sensitive bulk manufacturing, general electronics repair, educational settings, and for applications where leaded solder is still permissible.

The Tin Wire Sn15 Pb85 alloy finds its strength in specific, value-driven soldering environments. Its cheap price and reliable performance make it a staple in two main areas:

1. Factory Batch Soldering of Electronics: In mass production of consumer electronics, appliances, and automotive modules where cost control is critical, Tin Wire 15 85 is often used for wave soldering or selective soldering of through-hole components. Its performance is perfectly acceptable for creating durable electrical connections on circuit boards that are not subject to extreme miniaturization or stress.

2. Repair Shop for Electrical Appliances: Repair technicians fixing TVs, audio equipment, power supplies, and household appliances benefit greatly from Tin Wire Sn15 Pb85. The solder works well for replacing capacitors, resistors, connectors, and other larger components commonly found in such devices. Purchasing Tin Wire Sn15 Pb85 500g 0.8mm or 800g 0.8mm reels provides excellent value for a busy workshop.

This FAQ section addresses common queries from potential users of Tin Wire Sn15 Pb85.

Q1: Is Tin Wire Sn15 Pb85 suitable for fine surface-mount device (SMD) soldering?

A: While it can be used for larger SMD components, Tin Wire 15 85 0.8mm is not generally recommended for fine-pitch ICs or tiny components. Its wetting properties and higher melting range are less ideal for the precision and thermal control needed in delicate SMD work. Sn60Pb40 or lead-free alternatives with finer diameters are better suited for that purpose.

Q2: What type of flux core does this wire typically have, and is it sufficient?

A: Tin Wire Sn15 Pb85 commonly comes with a standard rosin (RA) or rosin-mildly activated (RMA) flux core. This is generally sufficient for general circuit board soldering where boards are not heavily oxidized. For dirtier or older boards in repair scenarios, additional external flux may be beneficial to ensure proper joint formation.

Q3: Why is the 0.8mm diameter so commonly offered for Tin Wire Sn15 Pb85 0.8mm?

A: The 0.8mm diameter is a versatile "middle-ground" size. It delivers enough solder volume quickly for larger joints (efficient for factories) while still allowing adequate control for manual work in repair shops. It fits a broad spectrum of tasks, simplifying inventory for suppliers and users of Tin Wire Sn15 Pb85 for Circuit Board projects.

Q4: How does the reel weight I choose impact my work?

A: Reel weight affects cost-efficiency and workflow. A Tin Wire Sn15 Pb85 100g 0.8mm reel is great for testing or occasional use. For sustained work, the Tin Wire Sn15 Pb85 1000g 0.8mm reel offers the lowest cost per gram and minimizes changeover interruptions. The 400g, 500g, and 800g sizes offer progressive steps in capacity.

Q5: Can I use Tin Wire 15 85 for electronics that require lead-free compliance (e.g., RoHS)?

A: No. Tin Wire Sn15 Pb85 contains a high percentage of lead and is not compliant with lead-free regulations like RoHS. It is intended for use in exempted categories, prototypes, repair of legacy equipment, or in regions where such regulations do not apply. Always verify the material requirements for your specific product and market.

To achieve the best results with this economical alloy, follow these guidelines:

Temperature Settings: Set your soldering iron to a higher temperature than you might for Sn60Pb40—typically between 400°C and 450°C . This accounts for the higher melting range of Tin Wire 15 85.

Cleanliness is Key: Ensure the circuit board pads and component leads are clean. Use isopropyl alcohol or a specialized cleaner if needed, especially in repair scenarios.

Proper Technique: Apply the iron tip to heat both the pad and the lead simultaneously. Then, feed the Tin Wire Sn15 Pb85 0.8mm into the junction, not directly onto the iron tip. Allow the solder to flow freely and form a concave fillet.

Manage Expectations: Joints will have a duller, grayer appearance compared to shiny Sn60Pb40 joints. This is normal for this alloy and does not necessarily indicate a cold joint. Focus on ensuring the solder has wetted all surfaces properly.

Ventilation: As with any soldering, ensure your workspace is well-ventilated to avoid inhaling fumes from the flux core.

For cost-conscious manufacturing and practical repair work, Tin Wire 15 85 stands out as a remarkably effective solution. Its significant price advantage over Sn60Pb40, combined with fully acceptable soldering quality for a wide array of applications, makes it a staple for businesses focused on efficiency and bottom-line results. Whether you opt for the convenient Tin Wire Sn15 Pb85 100g 0.8mm for your toolkit or the industrial Tin Wire Sn15 Pb85 1000g 0.8mm for your production line, you are selecting a product designed for value. By understanding its properties—embodied in keywords like Tin Wire Sn15 Pb85 for Circuit Board and Tin Wire 15 85 0.8mm—and applying the correct techniques, you can leverage Tin Wire Sn15 Pb85 to produce reliable electronic assemblies and repairs while maintaining a firm grip on your consumables budget.

Contact us:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: 008613450770997

In the demanding world of electronics manufacturing and repair, balancing cost with performance is a constant challenge. Enter Tin Wire Sn15 Pb85, a robust and economical solder alloy that delivers dependable results without straining your budget. This comprehensive guide explores the specifics of this 15% tin and 85% lead composition wire, particularly in the popular 0.8mm diameter, available in versatile reel weights from 100g to 1000g. Designed for general circuit board soldering, this alloy presents a compelling alternative to more expensive options like Sn60Pb40, making it ideal for factory production lines and repair workshops where volume and value are paramount. While its performance is distinct from high-tin alloys, its "good enough" welding quality for many applications, combined with its cheap price, positions Tin Wire 15 85 as a smart choice for bulk soldering operations and routine electrical repairs.

Tin Wire Sn15 Pb85 is a solder alloy composed of 15% tin (Sn) and 85% lead (Pb). This eutectic-like alloy has a melting point range that is higher than standard tin-lead eutectic (Sn63Pb37 or Sn60Pb40), typically beginning around 183°C (361°F) and becoming fully molten at a higher temperature. This specific ratio prioritizes cost savings—since tin is more expensive than lead—while retaining sufficient tin content to create a metallic bond with copper surfaces on circuit boards. The Tin Wire 15 85 formulation offers excellent wettability for general purposes, producing reliable solder joints with good mechanical strength for applications that do not require lead-free compliance. Its characteristics make the Tin Wire Sn15 Pb85 for Circuit Board work a practical reality for countless projects, especially when used with appropriate fluxes and techniques.

The diameter of solder wire is crucial for controlled application and efficient consumption. The Tin Wire 15 85 0.8mm variant strikes an ideal balance for a wide range of general soldering tasks. This 0.8mm diameter is substantial enough to allow for rapid deposition of solder, speeding up work in high-volume environments like factory assembly lines. Simultaneously, it is fine enough to permit reasonable control for through-hole component soldering, larger surface-mount pads, and general repair work on circuit boards. The Tin Wire Sn15 Pb85 0.8mm provides a smooth feed from the reel, minimizes waste, and is compatible with most standard soldering irons and automated dispensers. Its versatility across different reel sizes, from the compact Tin Wire Sn15 Pb85 100g 0.8mm to the bulk Tin Wire Sn15 Pb85 1000g 0.8mm, means one diameter can often suffice for multiple soldering stations within a facility.

Flexibility in packaging is key for operational efficiency. Tin Wire Sn15 Pb85 is thoughtfully offered in a range of reel weights to match different usage scales, all featuring the practical 0.8mm diameter.

Tin Wire Sn15 Pb85 100g 0.8mm: The perfect starter or trial size. This compact reel is excellent for repair technicians, hobbyists, or for low-volume tasks where portability is important. It allows users to test the performance of Tin Wire 15 85 without a large upfront investment.

Tin Wire Sn15 Pb85 400g 0.8mm & Tin Wire Sn15 Pb85 500g 0.8mm: These mid-range sizes are workhorses for busy repair shops and small to medium batch production. The Tin Wire Sn15 Pb85 500g 0.8mm reel offers a great balance between capacity and manageability, reducing the frequency of reel changes compared to the 100g size.

Tin Wire Sn15 Pb85 800g 0.8mm & Tin Wire Sn15 Pb85 1000g 0.8mm: These are the bulk industrial choices. The Tin Wire Sn15 Pb85 1000g 0.8mm reel maximizes value for high-throughput factory environments. It minimizes downtime for reloading and offers the lowest cost per gram, directly supporting the core advantage of a cheap price for bulk soldering operations on general circuit boards.

A primary reason for the popularity of Tin Wire Sn15 Pb85 is its significant cost advantage over the more common Solder Wire Sn60Pb40 alloy. This section breaks down the key differences.

Cost Savings: The higher lead content in Tin Wire 15 85 makes it substantially less expensive. For operations that go through kilograms of solder weekly, this translates to direct and considerable reductions in consumable costs.

Performance Considerations: Sn60Pb40 is a eutectic alloy with a sharp melting point (around 183°C), excellent flow, and strong, shiny joints. Tin Wire Sn15 Pb85 has a plastic range during melting, which can require slightly different technique. Its joints may appear duller and have lower tensile strength than Sn60Pb40. However, for many general circuit board soldering applications—such as through-hole components, wire terminations, and large tabs—the mechanical and electrical performance of Tin Wire Sn15 Pb85 is entirely adequate ("good enough"). The key is matching the alloy to the application's demands.

Best Use Cases: Choose Sn60Pb40 for fine-pitch SMD work, high-reliability military/aerospace applications, or where superior joint aesthetics are required. Choose Tin Wire Sn15 Pb85 for Circuit Board soldering in cost-sensitive bulk manufacturing, general electronics repair, educational settings, and for applications where leaded solder is still permissible.

The Tin Wire Sn15 Pb85 alloy finds its strength in specific, value-driven soldering environments. Its cheap price and reliable performance make it a staple in two main areas:

1. Factory Batch Soldering of Electronics: In mass production of consumer electronics, appliances, and automotive modules where cost control is critical, Tin Wire 15 85 is often used for wave soldering or selective soldering of through-hole components. Its performance is perfectly acceptable for creating durable electrical connections on circuit boards that are not subject to extreme miniaturization or stress.

2. Repair Shop for Electrical Appliances: Repair technicians fixing TVs, audio equipment, power supplies, and household appliances benefit greatly from Tin Wire Sn15 Pb85. The solder works well for replacing capacitors, resistors, connectors, and other larger components commonly found in such devices. Purchasing Tin Wire Sn15 Pb85 500g 0.8mm or 800g 0.8mm reels provides excellent value for a busy workshop.

This FAQ section addresses common queries from potential users of Tin Wire Sn15 Pb85.

Q1: Is Tin Wire Sn15 Pb85 suitable for fine surface-mount device (SMD) soldering?

A: While it can be used for larger SMD components, Tin Wire 15 85 0.8mm is not generally recommended for fine-pitch ICs or tiny components. Its wetting properties and higher melting range are less ideal for the precision and thermal control needed in delicate SMD work. Sn60Pb40 or lead-free alternatives with finer diameters are better suited for that purpose.

Q2: What type of flux core does this wire typically have, and is it sufficient?

A: Tin Wire Sn15 Pb85 commonly comes with a standard rosin (RA) or rosin-mildly activated (RMA) flux core. This is generally sufficient for general circuit board soldering where boards are not heavily oxidized. For dirtier or older boards in repair scenarios, additional external flux may be beneficial to ensure proper joint formation.

Q3: Why is the 0.8mm diameter so commonly offered for Tin Wire Sn15 Pb85 0.8mm?

A: The 0.8mm diameter is a versatile "middle-ground" size. It delivers enough solder volume quickly for larger joints (efficient for factories) while still allowing adequate control for manual work in repair shops. It fits a broad spectrum of tasks, simplifying inventory for suppliers and users of Tin Wire Sn15 Pb85 for Circuit Board projects.

Q4: How does the reel weight I choose impact my work?

A: Reel weight affects cost-efficiency and workflow. A Tin Wire Sn15 Pb85 100g 0.8mm reel is great for testing or occasional use. For sustained work, the Tin Wire Sn15 Pb85 1000g 0.8mm reel offers the lowest cost per gram and minimizes changeover interruptions. The 400g, 500g, and 800g sizes offer progressive steps in capacity.

Q5: Can I use Tin Wire 15 85 for electronics that require lead-free compliance (e.g., RoHS)?

A: No. Tin Wire Sn15 Pb85 contains a high percentage of lead and is not compliant with lead-free regulations like RoHS. It is intended for use in exempted categories, prototypes, repair of legacy equipment, or in regions where such regulations do not apply. Always verify the material requirements for your specific product and market.

To achieve the best results with this economical alloy, follow these guidelines:

Temperature Settings: Set your soldering iron to a higher temperature than you might for Sn60Pb40—typically between 400°C and 450°C . This accounts for the higher melting range of Tin Wire 15 85.

Cleanliness is Key: Ensure the circuit board pads and component leads are clean. Use isopropyl alcohol or a specialized cleaner if needed, especially in repair scenarios.

Proper Technique: Apply the iron tip to heat both the pad and the lead simultaneously. Then, feed the Tin Wire Sn15 Pb85 0.8mm into the junction, not directly onto the iron tip. Allow the solder to flow freely and form a concave fillet.

Manage Expectations: Joints will have a duller, grayer appearance compared to shiny Sn60Pb40 joints. This is normal for this alloy and does not necessarily indicate a cold joint. Focus on ensuring the solder has wetted all surfaces properly.

Ventilation: As with any soldering, ensure your workspace is well-ventilated to avoid inhaling fumes from the flux core.

For cost-conscious manufacturing and practical repair work, Tin Wire 15 85 stands out as a remarkably effective solution. Its significant price advantage over Sn60Pb40, combined with fully acceptable soldering quality for a wide array of applications, makes it a staple for businesses focused on efficiency and bottom-line results. Whether you opt for the convenient Tin Wire Sn15 Pb85 100g 0.8mm for your toolkit or the industrial Tin Wire Sn15 Pb85 1000g 0.8mm for your production line, you are selecting a product designed for value. By understanding its properties—embodied in keywords like Tin Wire Sn15 Pb85 for Circuit Board and Tin Wire 15 85 0.8mm—and applying the correct techniques, you can leverage Tin Wire Sn15 Pb85 to produce reliable electronic assemblies and repairs while maintaining a firm grip on your consumables budget.

Contact us:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: 008613450770997

The selection of solder is a foundational element in the successful assembly and repair of LED lighting systems. The eutectic 63 37 sn pb solder offers an unparalleled combination of a low melting point, excellent wettability, and joint reliability that is perfectly suited to the thermal sensitivity of LED components. By understanding the specific applications for each diameter—from the precision of 63 37 sn pb solder 1.0mm to the power of 63 37 sn pb solder 2.0mm—you can dramatically improve the quality and efficiency of your work. Packaging this superior alloy as solder in a reel, specifically in a 63 37 sn pb solder 1 kg reel, adds layers of practicality, economy, and consistency that benefit everyone from the professional production engineer to the meticulous hobbyist. Therefore, equipping your workspace with the appropriate diameter of 63 37 sn pb solder for LED Lights is not just a purchase; it is an investment in achieving superior, reliable, and professional results in all you

Our comprehensive range of 63 37 leaded wire solder for electronics is meticulously designed to meet the exacting demands of modern electronics work. The eutectic 63/37 tin-lead alloy guarantees reliable, shiny joints free from cold solder defects. The availability of both 63 37 leaded solder 0.6mm for precision tasks and 63 37 leaded solder 0.9mm for versatile general-purpose work ensures you have the right tool for every job. Furthermore, our flexible packaging—from the bulk 63 37 leaded solder 454g for professionals, to the standard 63 37 leaded solder 227g, and the accessible 63 37 leaded solder 100g for beginners—means there is a perfect option for every user and budget. Elevate your soldering work with the proven performance and quality of genuine 63 37 leaded solder.

Welcome to XF Solder, a leading manufacturer from China dedicated to producing high-quality soldering materials for the global market. We specialize in creating reliable, consistent, and performance-driven solder products that meet the rigorous demands of various industries. Our flagship product, the 60 40 Solder .032'' 1 lb spool, represents the gold standard in through-hole and general-purpose electronics assembly. This article provides a detailed overview of why this specific formulation and packaging is an indispensable inventory item for distributors, a superior choice for importers seeking quality from China, and a perfect 60 40 Solder 1 lb for Wholesale operations globally. We will explore its technical specifications, unparalleled benefits, and the strategic advantage it offers in the competitive electronics supply chain.

The combination of the proven 60 sn 40 pb alloy, the convenience of three standard diameters (1.6mm, 1.8mm, 2mm), and the economic 1lb (454g) packaging makes this product an indispensable tool for anyone involved in creating or repairing electrical assemblies. Whether you are a seasoned engineer working on complex industrial systems or a hobbyist bringing your first circuit to life, this 60 40 sn pb wire solder provides the performance, reliability, and value you need to ensure every connection is perfect. Stock up on this classic soldering solution today and experience the difference that quality materials make.