| Availability: | |

|---|---|

| Quantity: | |

In the intricate world of electronics manufacturing and repair, the choice of solder is foundational. Among the myriad of options, 60 40 tin lead rosin core flux solder stands as a time-tested, reliable standard. This specific alloy, comprising 60% tin and 40% lead (Sn60 Pb40), combined with a rosin flux core, has been the backbone of electrical component assembly for decades. Its eutectic properties—melting and solidifying at a single, low temperature of around 188°C (370°F)—make it exceptionally user-friendly, providing smooth, shiny joints with minimal risk of cold solder defects. This comprehensive guide delves into the specifics of this indispensable material, particularly focusing on the popular 60 40 tin lead solder 1.0mm diameter and its availability in convenient reel weights like 60 40 tin lead rosin core flux solder 1/2lb, 1lb, and 2lb. Whether you're a professional technician, a hobbyist, or involved in production, understanding this solder's characteristics and applications is crucial for successful projects.

60 40 tin lead solder is an alloy where the precise balance of 60% tin and 40% lead creates its unique eutectic characteristic. The "rosin core flux" denotes the internal channel of flux—a mild, non-corrosive cleaning agent—that runs through the center of the solder wire. This built-in flux is critical, as it cleans the metal surfaces of oxides during soldering, allowing the molten solder to flow and bond effectively. The Sn60 Pb40 rosin core flux solder offers several key advantages:

Excellent Wettability: It flows smoothly onto copper tracks and component leads.

Predictable Solidification: As a eutectic alloy, it transitions directly from liquid to solid without a "pasty" phase, reducing defects.

Strong, Reliable Joints: It forms durable electrical and mechanical connections.

User-Friendly: Its lower melting point compared to lead-free alternatives makes it easier to work with, especially for manual soldering.

It's important to note that due to lead content, its use is often restricted in commercial consumer electronics under regulations like RoHS. However, it remains extensively used and preferred in aerospace, defense, automotive, and certain industrial applications where reliability is paramount, as well as in prototyping, repair, and hobbyist electronics where lead-free mandates may not apply.

Selecting the right solder directly impacts the quality, speed, and reliability of your assembly work. 60 40 solder for Component Assembly is frequently the top choice for several compelling reasons. The rosin core flux is self-contained and automatically applied in the correct proportion as you solder, eliminating the separate step of flux application and streamlining the workflow. The flux is also naturally non-conductive and, being rosin-based, is generally non-corrosive, leaving a residue that is often benign for many applications, though cleaning may be required in high-impedance circuits. For manual assembly, rework, and repair—tasks that demand precision and control—the performance of 60 40 rosin core flux solder is often considered superior to many lead-free varieties. Its superior wetting action and lower working temperature reduce thermal stress on sensitive components, a critical factor when working with vintage electronics or delicate parts. The consistent results it delivers make it an ideal 60 40 solder for Component Assembly across a wide range of precision tasks.

The diameter of your solder wire is not a minor detail—it's a critical variable that affects joint quality, solder volume control, and overall efficiency. The 60 40 tin lead solder 1.0mm size represents an excellent, versatile middle ground for a vast array of electrical assembly work.

The 60 40 tin lead rosin core flux solder 1.0mm is perfectly suited for general-purpose through-hole component soldering. It provides an ideal balance between deposition speed and control. This diameter is excellent for:

Soldering standard through-hole resistors, capacitors, DIP ICs, and connectors.

General PCB repair and rework.

Building and assembling prototype boards.

Automotive wiring and connector repairs (where permitted).

It offers enough material to quickly form a joint on larger pads or pins but is still thin enough to allow for precise work on medium-pitch components.

Compared to thinner diameters (like 0.5mm or 0.7mm), the 60 40 tin lead rosin core flux solder 1.0mm allows for faster work on standard-sized joints, as less wire feed is required to deposit the same volume of solder. Compared to thicker wires (like 1.2mm or 1.5mm), it provides significantly better control, reducing the risk of over-soldering or creating bridges between closely spaced pins. For the majority of technicians and makers who work on a mix of component sizes, the 1.0mm diameter of 60 40 tin lead rosin core flux solder is the most practical and efficient choice, minimizing the need to switch reels constantly.

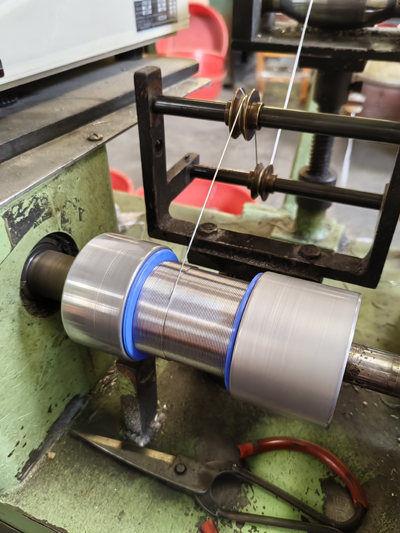

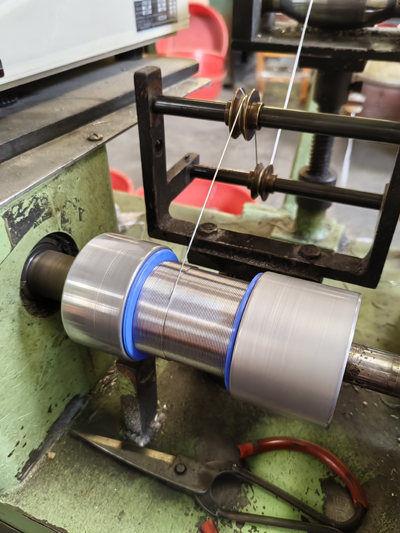

60 40 tin lead rosin core flux solder is packaged in various reel weights to suit different usage patterns, from occasional hobbyist use to continuous professional production. Understanding which reel size fits your needs can optimize cost and workspace organization.

The 60 40 tin lead rosin core flux solder 1/2lb reel is the ideal entry point or choice for low-volume users.

Best For: Hobbyists, students, occasional DIY repair jobs, and technicians who need a variety of solder types on hand for different tasks.

Advantages: Lower upfront cost, takes up minimal space in a toolbox or bench drawer, and is perfect for trying out the alloy if you're new to it.

Considerations: The cost per gram is typically higher than larger reels.

The 60 40 tin lead rosin core flux solder 1lb package is arguably the most popular and versatile option.

Best For: Serious electronics hobbyists, frequent repair technicians, small to medium-sized assembly shops, and educational settings.

Advantages: Offers an excellent balance between volume and manageability. It provides a substantial amount of solder for many projects without being overly bulky, and it usually offers better value per ounce than the 1/2lb size. The 1lb reel fits most standard bench-top solder holders.

The 60 40 tin lead rosin core flux solder 2lb reel is designed for high-volume usage and professional environments.

Best For: Small manufacturing lines, repair depots with high throughput, or any setting where soldering is a daily, continuous activity.

Advantages: The best value per unit weight, minimizing the frequency of reel changes and material ordering. It maximizes uptime in a production setting.

Considerations: Requires a sturdy holder or dispenser due to its size and weight. It is less practical for mobile toolkits.

Yes, 60 40 tin lead rosin core flux solder is legal to purchase and use in many applications. However, its use in commercial consumer electronics placed on the market in the EU, UK, China, and many other regions is restricted by RoHS (Restriction of Hazardous Substances) directives. Exemptions exist for critical industries like aerospace, military, medical (some categories), and automotive (certain applications). It is widely used for repair, maintenance, prototyping, and in hobbyist projects not intended for commercial sale. Always check your local and industry-specific regulations.

60 40 solder for Component Assembly generally offers a lower melting point (188°C vs. 217°C+ for common SAC alloys), better wettability, and a smoother, shinier joint appearance. It is often considered easier to work with manually, especially for intricate or rework tasks, as it flows more readily. Lead-free solders can be more "sticky," have a higher working temperature (increasing thermal stress), and are more prone to tin whisker growth. The primary advantage of lead-free is its environmental and health compliance for commercial goods.

When stored properly in a cool, dry place in its original sealed packaging, Sn60 Pb40 rosin core flux solder has a very long shelf life—typically several years. The main concern is the flux degradation. Over many years, especially in poor conditions, the rosin flux can become less active or the wire can oxidize. If the solder wire appears dull, discolored, or the flux seems dry and doesn't sputter properly when heated, its performance may be compromised.

While the 60 40 tin lead rosin core flux solder 1.0mm diameter can be used for some larger SMD components with careful technique, it is generally too thick for most fine-pitch SMD work. For hand-soldering SMDs like small resistors, capacitors, or ICs with fine leads, a thinner diameter (such as 0.5mm or 0.7mm) of 60 40 rosin core flux solder is highly recommended to prevent bridging and allow for precise solder paste-like application.

Rosin flux residue is typically non-corrosive and non-conductive in its pure state. For many prototypes, hobby projects, and non-critical circuits, cleaning is not strictly necessary. However, the residue can be sticky and attract dust, and in high-humidity environments or on high-impedance, high-voltage, or RF circuits, it can potentially lead to leakage currents or dendritic growth. For professional, reliable, and clean assemblies—especially in harsh environments—it is good practice to clean the residue using isopropyl alcohol or a dedicated flux remover.

To achieve perfect, reliable joints with your 60 40 tin lead solder, following proven techniques is essential.

Cleanliness is Key: Ensure all component leads and PCB pads are clean and free of oxidation, oils, or old solder. The rosin flux helps, but starting clean is crucial.

Proper Temperature: Set your soldering iron to a temperature appropriate for the joint size, typically between 315°C and 370°C (600°F - 700°F). The goal is to heat the joint components rapidly, not just melt the solder onto the iron.

The Heating Technique: Apply the iron tip to both the component lead and the copper pad simultaneously to heat them evenly. After 1-2 seconds, feed the 60 40 tin lead rosin core flux solder 1.0mm wire into the joint, not directly onto the iron tip. The solder should melt and flow smoothly around the lead and into the pad.

Adequate Flux: If you are soldering old or heavily oxidized parts, the internal flux in the solder may not be sufficient. Applying a small amount of additional liquid rosin flux to the joint before soldering can dramatically improve results.

Joint Inspection: A good solder joint made with 60 40 rosin core flux solder will be smooth, bright, and shiny, with a concave fillet that covers the pad and wets up the lead. It should not be dull, grainy, or ball-shaped.

Despite the global shift towards lead-free alternatives in commercial manufacturing, the 60 40 tin lead rosin core flux solder remains an indispensable tool in the electronics industry. Its unbeatable combination of ease of use, reliable performance, and excellent joint quality secures its place on the workbenches of repair technicians, aerospace engineers, automotive electricians, and electronics enthusiasts worldwide. Whether you select the versatile 60 40 tin lead rosin core flux solder 1.0mm diameter on a convenient 60 40 tin lead rosin core flux solder 1lb reel for your home lab, or a large 2lb reel for professional use, you are choosing a material with a proven track record. By understanding its properties, applications, and the best practices for its use, you can leverage the full potential of this classic Sn60 Pb40 rosin core flux solder to create strong, durable, and electrically sound connections for all your electrical component assembly projects.

Contact us:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: 008613450770997

In the intricate world of electronics manufacturing and repair, the choice of solder is foundational. Among the myriad of options, 60 40 tin lead rosin core flux solder stands as a time-tested, reliable standard. This specific alloy, comprising 60% tin and 40% lead (Sn60 Pb40), combined with a rosin flux core, has been the backbone of electrical component assembly for decades. Its eutectic properties—melting and solidifying at a single, low temperature of around 188°C (370°F)—make it exceptionally user-friendly, providing smooth, shiny joints with minimal risk of cold solder defects. This comprehensive guide delves into the specifics of this indispensable material, particularly focusing on the popular 60 40 tin lead solder 1.0mm diameter and its availability in convenient reel weights like 60 40 tin lead rosin core flux solder 1/2lb, 1lb, and 2lb. Whether you're a professional technician, a hobbyist, or involved in production, understanding this solder's characteristics and applications is crucial for successful projects.

60 40 tin lead solder is an alloy where the precise balance of 60% tin and 40% lead creates its unique eutectic characteristic. The "rosin core flux" denotes the internal channel of flux—a mild, non-corrosive cleaning agent—that runs through the center of the solder wire. This built-in flux is critical, as it cleans the metal surfaces of oxides during soldering, allowing the molten solder to flow and bond effectively. The Sn60 Pb40 rosin core flux solder offers several key advantages:

Excellent Wettability: It flows smoothly onto copper tracks and component leads.

Predictable Solidification: As a eutectic alloy, it transitions directly from liquid to solid without a "pasty" phase, reducing defects.

Strong, Reliable Joints: It forms durable electrical and mechanical connections.

User-Friendly: Its lower melting point compared to lead-free alternatives makes it easier to work with, especially for manual soldering.

It's important to note that due to lead content, its use is often restricted in commercial consumer electronics under regulations like RoHS. However, it remains extensively used and preferred in aerospace, defense, automotive, and certain industrial applications where reliability is paramount, as well as in prototyping, repair, and hobbyist electronics where lead-free mandates may not apply.

Selecting the right solder directly impacts the quality, speed, and reliability of your assembly work. 60 40 solder for Component Assembly is frequently the top choice for several compelling reasons. The rosin core flux is self-contained and automatically applied in the correct proportion as you solder, eliminating the separate step of flux application and streamlining the workflow. The flux is also naturally non-conductive and, being rosin-based, is generally non-corrosive, leaving a residue that is often benign for many applications, though cleaning may be required in high-impedance circuits. For manual assembly, rework, and repair—tasks that demand precision and control—the performance of 60 40 rosin core flux solder is often considered superior to many lead-free varieties. Its superior wetting action and lower working temperature reduce thermal stress on sensitive components, a critical factor when working with vintage electronics or delicate parts. The consistent results it delivers make it an ideal 60 40 solder for Component Assembly across a wide range of precision tasks.

The diameter of your solder wire is not a minor detail—it's a critical variable that affects joint quality, solder volume control, and overall efficiency. The 60 40 tin lead solder 1.0mm size represents an excellent, versatile middle ground for a vast array of electrical assembly work.

The 60 40 tin lead rosin core flux solder 1.0mm is perfectly suited for general-purpose through-hole component soldering. It provides an ideal balance between deposition speed and control. This diameter is excellent for:

Soldering standard through-hole resistors, capacitors, DIP ICs, and connectors.

General PCB repair and rework.

Building and assembling prototype boards.

Automotive wiring and connector repairs (where permitted).

It offers enough material to quickly form a joint on larger pads or pins but is still thin enough to allow for precise work on medium-pitch components.

Compared to thinner diameters (like 0.5mm or 0.7mm), the 60 40 tin lead rosin core flux solder 1.0mm allows for faster work on standard-sized joints, as less wire feed is required to deposit the same volume of solder. Compared to thicker wires (like 1.2mm or 1.5mm), it provides significantly better control, reducing the risk of over-soldering or creating bridges between closely spaced pins. For the majority of technicians and makers who work on a mix of component sizes, the 1.0mm diameter of 60 40 tin lead rosin core flux solder is the most practical and efficient choice, minimizing the need to switch reels constantly.

60 40 tin lead rosin core flux solder is packaged in various reel weights to suit different usage patterns, from occasional hobbyist use to continuous professional production. Understanding which reel size fits your needs can optimize cost and workspace organization.

The 60 40 tin lead rosin core flux solder 1/2lb reel is the ideal entry point or choice for low-volume users.

Best For: Hobbyists, students, occasional DIY repair jobs, and technicians who need a variety of solder types on hand for different tasks.

Advantages: Lower upfront cost, takes up minimal space in a toolbox or bench drawer, and is perfect for trying out the alloy if you're new to it.

Considerations: The cost per gram is typically higher than larger reels.

The 60 40 tin lead rosin core flux solder 1lb package is arguably the most popular and versatile option.

Best For: Serious electronics hobbyists, frequent repair technicians, small to medium-sized assembly shops, and educational settings.

Advantages: Offers an excellent balance between volume and manageability. It provides a substantial amount of solder for many projects without being overly bulky, and it usually offers better value per ounce than the 1/2lb size. The 1lb reel fits most standard bench-top solder holders.

The 60 40 tin lead rosin core flux solder 2lb reel is designed for high-volume usage and professional environments.

Best For: Small manufacturing lines, repair depots with high throughput, or any setting where soldering is a daily, continuous activity.

Advantages: The best value per unit weight, minimizing the frequency of reel changes and material ordering. It maximizes uptime in a production setting.

Considerations: Requires a sturdy holder or dispenser due to its size and weight. It is less practical for mobile toolkits.

Yes, 60 40 tin lead rosin core flux solder is legal to purchase and use in many applications. However, its use in commercial consumer electronics placed on the market in the EU, UK, China, and many other regions is restricted by RoHS (Restriction of Hazardous Substances) directives. Exemptions exist for critical industries like aerospace, military, medical (some categories), and automotive (certain applications). It is widely used for repair, maintenance, prototyping, and in hobbyist projects not intended for commercial sale. Always check your local and industry-specific regulations.

60 40 solder for Component Assembly generally offers a lower melting point (188°C vs. 217°C+ for common SAC alloys), better wettability, and a smoother, shinier joint appearance. It is often considered easier to work with manually, especially for intricate or rework tasks, as it flows more readily. Lead-free solders can be more "sticky," have a higher working temperature (increasing thermal stress), and are more prone to tin whisker growth. The primary advantage of lead-free is its environmental and health compliance for commercial goods.

When stored properly in a cool, dry place in its original sealed packaging, Sn60 Pb40 rosin core flux solder has a very long shelf life—typically several years. The main concern is the flux degradation. Over many years, especially in poor conditions, the rosin flux can become less active or the wire can oxidize. If the solder wire appears dull, discolored, or the flux seems dry and doesn't sputter properly when heated, its performance may be compromised.

While the 60 40 tin lead rosin core flux solder 1.0mm diameter can be used for some larger SMD components with careful technique, it is generally too thick for most fine-pitch SMD work. For hand-soldering SMDs like small resistors, capacitors, or ICs with fine leads, a thinner diameter (such as 0.5mm or 0.7mm) of 60 40 rosin core flux solder is highly recommended to prevent bridging and allow for precise solder paste-like application.

Rosin flux residue is typically non-corrosive and non-conductive in its pure state. For many prototypes, hobby projects, and non-critical circuits, cleaning is not strictly necessary. However, the residue can be sticky and attract dust, and in high-humidity environments or on high-impedance, high-voltage, or RF circuits, it can potentially lead to leakage currents or dendritic growth. For professional, reliable, and clean assemblies—especially in harsh environments—it is good practice to clean the residue using isopropyl alcohol or a dedicated flux remover.

To achieve perfect, reliable joints with your 60 40 tin lead solder, following proven techniques is essential.

Cleanliness is Key: Ensure all component leads and PCB pads are clean and free of oxidation, oils, or old solder. The rosin flux helps, but starting clean is crucial.

Proper Temperature: Set your soldering iron to a temperature appropriate for the joint size, typically between 315°C and 370°C (600°F - 700°F). The goal is to heat the joint components rapidly, not just melt the solder onto the iron.

The Heating Technique: Apply the iron tip to both the component lead and the copper pad simultaneously to heat them evenly. After 1-2 seconds, feed the 60 40 tin lead rosin core flux solder 1.0mm wire into the joint, not directly onto the iron tip. The solder should melt and flow smoothly around the lead and into the pad.

Adequate Flux: If you are soldering old or heavily oxidized parts, the internal flux in the solder may not be sufficient. Applying a small amount of additional liquid rosin flux to the joint before soldering can dramatically improve results.

Joint Inspection: A good solder joint made with 60 40 rosin core flux solder will be smooth, bright, and shiny, with a concave fillet that covers the pad and wets up the lead. It should not be dull, grainy, or ball-shaped.

Despite the global shift towards lead-free alternatives in commercial manufacturing, the 60 40 tin lead rosin core flux solder remains an indispensable tool in the electronics industry. Its unbeatable combination of ease of use, reliable performance, and excellent joint quality secures its place on the workbenches of repair technicians, aerospace engineers, automotive electricians, and electronics enthusiasts worldwide. Whether you select the versatile 60 40 tin lead rosin core flux solder 1.0mm diameter on a convenient 60 40 tin lead rosin core flux solder 1lb reel for your home lab, or a large 2lb reel for professional use, you are choosing a material with a proven track record. By understanding its properties, applications, and the best practices for its use, you can leverage the full potential of this classic Sn60 Pb40 rosin core flux solder to create strong, durable, and electrically sound connections for all your electrical component assembly projects.

Contact us:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: 008613450770997

The selection of solder is a foundational element in the successful assembly and repair of LED lighting systems. The eutectic 63 37 sn pb solder offers an unparalleled combination of a low melting point, excellent wettability, and joint reliability that is perfectly suited to the thermal sensitivity of LED components. By understanding the specific applications for each diameter—from the precision of 63 37 sn pb solder 1.0mm to the power of 63 37 sn pb solder 2.0mm—you can dramatically improve the quality and efficiency of your work. Packaging this superior alloy as solder in a reel, specifically in a 63 37 sn pb solder 1 kg reel, adds layers of practicality, economy, and consistency that benefit everyone from the professional production engineer to the meticulous hobbyist. Therefore, equipping your workspace with the appropriate diameter of 63 37 sn pb solder for LED Lights is not just a purchase; it is an investment in achieving superior, reliable, and professional results in all you

Our comprehensive range of 63 37 leaded wire solder for electronics is meticulously designed to meet the exacting demands of modern electronics work. The eutectic 63/37 tin-lead alloy guarantees reliable, shiny joints free from cold solder defects. The availability of both 63 37 leaded solder 0.6mm for precision tasks and 63 37 leaded solder 0.9mm for versatile general-purpose work ensures you have the right tool for every job. Furthermore, our flexible packaging—from the bulk 63 37 leaded solder 454g for professionals, to the standard 63 37 leaded solder 227g, and the accessible 63 37 leaded solder 100g for beginners—means there is a perfect option for every user and budget. Elevate your soldering work with the proven performance and quality of genuine 63 37 leaded solder.

Welcome to XF Solder, a leading manufacturer from China dedicated to producing high-quality soldering materials for the global market. We specialize in creating reliable, consistent, and performance-driven solder products that meet the rigorous demands of various industries. Our flagship product, the 60 40 Solder .032'' 1 lb spool, represents the gold standard in through-hole and general-purpose electronics assembly. This article provides a detailed overview of why this specific formulation and packaging is an indispensable inventory item for distributors, a superior choice for importers seeking quality from China, and a perfect 60 40 Solder 1 lb for Wholesale operations globally. We will explore its technical specifications, unparalleled benefits, and the strategic advantage it offers in the competitive electronics supply chain.

The combination of the proven 60 sn 40 pb alloy, the convenience of three standard diameters (1.6mm, 1.8mm, 2mm), and the economic 1lb (454g) packaging makes this product an indispensable tool for anyone involved in creating or repairing electrical assemblies. Whether you are a seasoned engineer working on complex industrial systems or a hobbyist bringing your first circuit to life, this 60 40 sn pb wire solder provides the performance, reliability, and value you need to ensure every connection is perfect. Stock up on this classic soldering solution today and experience the difference that quality materials make.