| Availability: | |

|---|---|

| Quantity: | |

Welcome to the comprehensive guide on one of the most reliable and cost-effective soldering materials available today: the 30 70 lead solder. As a premier 30 70 tin lead solder manufacturer, XF Sander takes pride in producing high-quality solders that meet diverse industrial and hobbyist needs. This 1500-word article will delve deep into the specifications, applications, benefits, and technical details of our flagship product: 30 70 Sn30 Pb70 Tin Lead Solder with a 1.6mm diameter, conveniently packaged in a 500g roll. Whether you're involved in electronics, plumbing, or automotive repairs, understanding the properties of tin solder Sn30 Pb70 can significantly enhance your work quality and efficiency. We'll explore why this solder alloy remains a popular choice despite the rise of lead-free alternatives, focusing on its performance, affordability, and versatility. By the end, you'll appreciate why sourcing from a trusted Chinese manufacturer like XF Solder ensures consistency and value for your projects.

Lead solder Sn30 Pb70 refers to a specific alloy composed of 30% tin and 70% lead. This composition is meticulously balanced to provide optimal soldering characteristics, making it a staple in many industries. The "Sn30" denotes the tin content, which contributes to the solder's wetting ability and strength, while "Pb70" indicates the lead portion, responsible for lowering the melting point and enhancing fluidity. As a 30 70 tin lead solder manufacturer, XF Solder ensures that each batch of tin solder Sn30 meets strict quality standards, resulting in a product that offers reliable joints and minimal defects. The 1.6mm diameter is ideal for a wide range of applications, from delicate electronic components to heavier-duty connections, providing just the right amount of material for efficient soldering. Packaged in a 500g roll, this 30 70 lead solder 500g option is perfect for both occasional use and high-volume production environments, offering convenience and long-lasting supply.

The 30 70 tin solder boasts several key properties that make it stand out. First, its melting point is approximately 260°C (500°F), which is lower than many lead-free alternatives, reducing the risk of thermal damage to components. This lead solder Sn30 alloy also exhibits excellent wettability, meaning it flows smoothly over surfaces to create strong, reliable bonds. The tin solder Sn30 Pb70 is known for its ductility and resistance to fatigue, making it suitable for applications subject to vibration or thermal cycling. Additionally, the 1.6mm diameter of this 30 70 lead solder 1.6mm product ensures easy handling and controlled application, minimizing waste. As a leading 30 70 tin lead solder manufacturer, XF Solder prioritizes consistency in these properties, ensuring that every roll of 30 70 lead solder delivers predictable performance. Its low cost further enhances its appeal, providing an economical solution without compromising on quality.

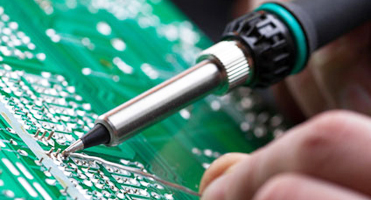

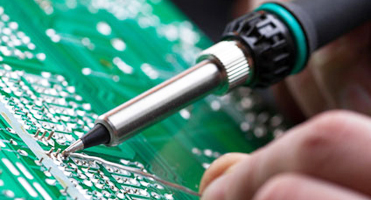

In the electronics industry, tin solder Sn30 is widely used for printed circuit board (PCB) assembly and repair. The 30 70 lead solder provides strong electrical connections and is particularly favored for through-hole components due to its reliable performance. The lead solder Sn30 Pb70 alloy ensures minimal solder bridging and good flux compatibility, which is crucial for complex PCB designs. As a trusted 30 70 tin lead solder manufacturer, XF Solder supplies this material to manufacturers who require consistent results in high-volume production. The 1.6mm diameter of our 30 70 lead solder 1.6mm variant allows for precise application in automated soldering equipment, while the 30 70 lead solder 500g roll size supports continuous operation without frequent reloading. This makes tin solder Sn30 Pb70 an efficient choice for everything from consumer electronics to industrial control systems.

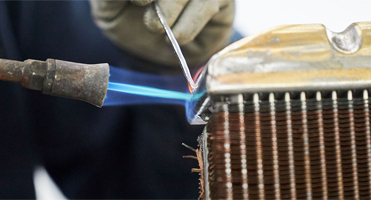

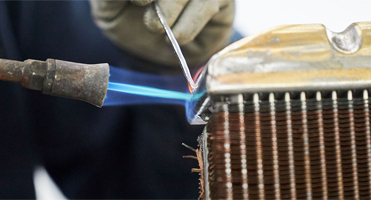

Beyond electronics, lead solder Sn30 Pb70 finds extensive use in plumbing and metal joining applications. Its low melting point and excellent flow characteristics make it ideal for sealing copper pipes and fittings, providing leak-proof joints that withstand pressure and corrosion. The 30 70 tin solder is also employed in automotive radiators, HVAC systems, and other metal fabrication tasks where durability is key. XF Solder, as a reputable 30 70 tin lead solder manufacturer, ensures that our product meets the rigorous demands of these industries. The 1.6mm diameter offers versatility for both manual and torch soldering, and the 30 70 lead solder 500g package is cost-effective for large projects. Despite increasing regulations in some regions, 30 70 lead solder remains popular in areas where its properties are unmatched by lead-free options, thanks to its proven track record and affordability.

One of the primary reasons for the enduring popularity of 30 70 lead solder is its cost-effectiveness. Compared to lead-free solders, which often require higher temperatures and more expensive fluxes, tin solder Sn30 Pb70 reduces overall production costs. As a dedicated 30 70 tin lead solder manufacturer, XF Solder leverages efficient production methods to offer competitive pricing on our 30 70 lead solder 500g rolls. This economy doesn't come at the expense of quality; each batch of lead solder Sn30 is tested for purity and performance, ensuring you get the best value. The 1.6mm diameter further enhances savings by minimizing waste and improving application efficiency. For businesses looking to optimize their budgets without sacrificing reliability, 30 70 tin solder from XF Solder is an intelligent choice.

When it comes to performance, tin solder Sn30 excels in creating strong, long-lasting joints. The 30 70 lead solder alloy is less prone to tin whiskers and other failure modes common in some alternatives, making it a reliable option for critical applications. Lead solder Sn30 Pb70 from XF Solder undergoes rigorous quality control to ensure consistent composition and diameter, which translates to predictable melting and wetting behavior. The 30 70 lead solder 1.6mm size is versatile enough for both fine-pitch work and larger connections, while the 30 70 lead solder 500g packaging ensures you have an ample supply on hand. As a leading 30 70 tin lead solder manufacturer, we prioritize customer satisfaction by delivering a product that meets the highest standards of durability and ease of use.

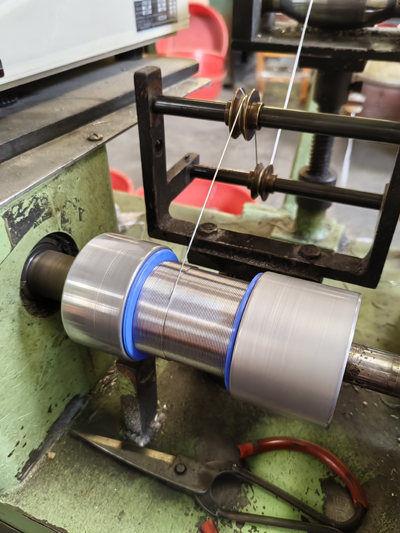

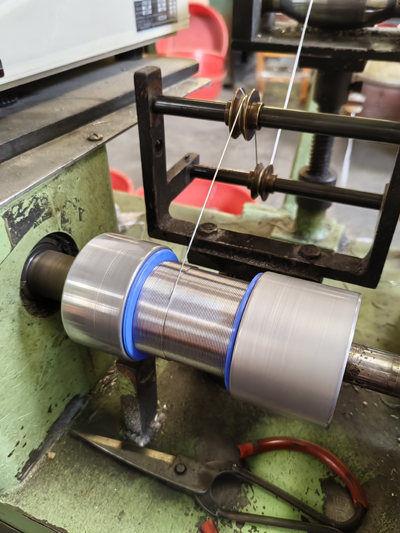

Our 30 70 lead solder comes with precise specifications tailored for optimal performance. The alloy composition is strictly Sn30 Pb70, meaning 30% tin and 70% lead, with impurities controlled to below 0.1%. The diameter is consistently 1.6mm, suitable for a wide range of soldering irons and machines. Each roll contains 500 grams of 30 70 lead solder 500g, providing substantial material for extended use. The lead solder Sn30 Pb70 is typically supplied on a sturdy spool with anti-tangle features, ensuring smooth unwinding during operation. As a professional 30 70 tin lead solder manufacturer, XF Solder includes flux-free options or can customize flux cores upon request. This attention to detail makes our tin solder Sn30 a preferred choice for professionals worldwide.

While lead solder Sn30 offers numerous benefits, it's essential to address safety and environmental aspects. Lead is a toxic material, so proper handling is crucial. Users should wear gloves and work in well-ventilated areas to avoid exposure. Disposal must comply with local regulations to prevent environmental contamination. As a responsible 30 70 tin lead solder manufacturer, XF Solder provides safety data sheets and guidelines for safe usage. We also encourage customers to explore lead-free alternatives if required by their industry standards. However, for applications where 30 70 tin solder is permissible, its performance advantages often outweigh the risks when managed correctly. The 30 70 lead solder 1.6mm diameter and 30 70 lead solder 500g roll are designed for efficient use, minimizing waste and potential hazards.

Choosing XF Solder as your 30 70 tin lead solder manufacturer means investing in quality and reliability. We implement strict quality control measures at every stage of production, from raw material selection to final packaging. Our tin solder Sn30 Pb70 is manufactured using high-purity metals and advanced extrusion technology, ensuring consistent diameter and alloy homogeneity. Each 30 70 lead solder roll is inspected for defects, guaranteeing that you receive a product that performs as expected. The 30 70 lead solder 1.6mm specification is maintained with tight tolerances, and the 30 70 lead solder 500g weight is accurately measured. By prioritizing quality, we help you achieve better soldering results with fewer rejects and rework.

As a Chinese 30 70 tin lead solder manufacturer, XF Solder offers significant advantages in terms of cost and scalability. Our location in a global manufacturing hub allows us to source materials efficiently and pass the savings on to our customers. This enables us to provide 30 70 lead solder at highly competitive prices without compromising on quality. We also have the capacity to handle large orders, making us an ideal partner for businesses with substantial sourcing needs. The tin solder Sn30 we produce meets international standards, and we offer flexible packaging options, including the popular 30 70 lead solder 500g roll. With a focus on customer service and timely delivery, XF Solder is your go-to source for reliable lead solder Sn30 Pb70.

In summary, the 30 70 Sn30 Pb70 Tin Lead Solder with a 1.6mm diameter in a 500g roll is a versatile, cost-effective solution for countless soldering applications. Its balanced composition as 30 70 lead solder ensures excellent performance in electronics, plumbing, and beyond. By sourcing from XF Solder, a reputable 30 70 tin lead solder manufacturer, you benefit from consistent quality, competitive pricing, and expert support. Whether you're looking for tin solder Sn30 for precision work or lead solder Sn30 Pb70 for heavy-duty joins, our product delivers on all fronts. Explore the advantages of this reliable solder today and experience the difference that professional-grade materials can make in your projects.

Contact us:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: 008613450770997

Welcome to the comprehensive guide on one of the most reliable and cost-effective soldering materials available today: the 30 70 lead solder. As a premier 30 70 tin lead solder manufacturer, XF Sander takes pride in producing high-quality solders that meet diverse industrial and hobbyist needs. This 1500-word article will delve deep into the specifications, applications, benefits, and technical details of our flagship product: 30 70 Sn30 Pb70 Tin Lead Solder with a 1.6mm diameter, conveniently packaged in a 500g roll. Whether you're involved in electronics, plumbing, or automotive repairs, understanding the properties of tin solder Sn30 Pb70 can significantly enhance your work quality and efficiency. We'll explore why this solder alloy remains a popular choice despite the rise of lead-free alternatives, focusing on its performance, affordability, and versatility. By the end, you'll appreciate why sourcing from a trusted Chinese manufacturer like XF Solder ensures consistency and value for your projects.

Lead solder Sn30 Pb70 refers to a specific alloy composed of 30% tin and 70% lead. This composition is meticulously balanced to provide optimal soldering characteristics, making it a staple in many industries. The "Sn30" denotes the tin content, which contributes to the solder's wetting ability and strength, while "Pb70" indicates the lead portion, responsible for lowering the melting point and enhancing fluidity. As a 30 70 tin lead solder manufacturer, XF Solder ensures that each batch of tin solder Sn30 meets strict quality standards, resulting in a product that offers reliable joints and minimal defects. The 1.6mm diameter is ideal for a wide range of applications, from delicate electronic components to heavier-duty connections, providing just the right amount of material for efficient soldering. Packaged in a 500g roll, this 30 70 lead solder 500g option is perfect for both occasional use and high-volume production environments, offering convenience and long-lasting supply.

The 30 70 tin solder boasts several key properties that make it stand out. First, its melting point is approximately 260°C (500°F), which is lower than many lead-free alternatives, reducing the risk of thermal damage to components. This lead solder Sn30 alloy also exhibits excellent wettability, meaning it flows smoothly over surfaces to create strong, reliable bonds. The tin solder Sn30 Pb70 is known for its ductility and resistance to fatigue, making it suitable for applications subject to vibration or thermal cycling. Additionally, the 1.6mm diameter of this 30 70 lead solder 1.6mm product ensures easy handling and controlled application, minimizing waste. As a leading 30 70 tin lead solder manufacturer, XF Solder prioritizes consistency in these properties, ensuring that every roll of 30 70 lead solder delivers predictable performance. Its low cost further enhances its appeal, providing an economical solution without compromising on quality.

In the electronics industry, tin solder Sn30 is widely used for printed circuit board (PCB) assembly and repair. The 30 70 lead solder provides strong electrical connections and is particularly favored for through-hole components due to its reliable performance. The lead solder Sn30 Pb70 alloy ensures minimal solder bridging and good flux compatibility, which is crucial for complex PCB designs. As a trusted 30 70 tin lead solder manufacturer, XF Solder supplies this material to manufacturers who require consistent results in high-volume production. The 1.6mm diameter of our 30 70 lead solder 1.6mm variant allows for precise application in automated soldering equipment, while the 30 70 lead solder 500g roll size supports continuous operation without frequent reloading. This makes tin solder Sn30 Pb70 an efficient choice for everything from consumer electronics to industrial control systems.

Beyond electronics, lead solder Sn30 Pb70 finds extensive use in plumbing and metal joining applications. Its low melting point and excellent flow characteristics make it ideal for sealing copper pipes and fittings, providing leak-proof joints that withstand pressure and corrosion. The 30 70 tin solder is also employed in automotive radiators, HVAC systems, and other metal fabrication tasks where durability is key. XF Solder, as a reputable 30 70 tin lead solder manufacturer, ensures that our product meets the rigorous demands of these industries. The 1.6mm diameter offers versatility for both manual and torch soldering, and the 30 70 lead solder 500g package is cost-effective for large projects. Despite increasing regulations in some regions, 30 70 lead solder remains popular in areas where its properties are unmatched by lead-free options, thanks to its proven track record and affordability.

One of the primary reasons for the enduring popularity of 30 70 lead solder is its cost-effectiveness. Compared to lead-free solders, which often require higher temperatures and more expensive fluxes, tin solder Sn30 Pb70 reduces overall production costs. As a dedicated 30 70 tin lead solder manufacturer, XF Solder leverages efficient production methods to offer competitive pricing on our 30 70 lead solder 500g rolls. This economy doesn't come at the expense of quality; each batch of lead solder Sn30 is tested for purity and performance, ensuring you get the best value. The 1.6mm diameter further enhances savings by minimizing waste and improving application efficiency. For businesses looking to optimize their budgets without sacrificing reliability, 30 70 tin solder from XF Solder is an intelligent choice.

When it comes to performance, tin solder Sn30 excels in creating strong, long-lasting joints. The 30 70 lead solder alloy is less prone to tin whiskers and other failure modes common in some alternatives, making it a reliable option for critical applications. Lead solder Sn30 Pb70 from XF Solder undergoes rigorous quality control to ensure consistent composition and diameter, which translates to predictable melting and wetting behavior. The 30 70 lead solder 1.6mm size is versatile enough for both fine-pitch work and larger connections, while the 30 70 lead solder 500g packaging ensures you have an ample supply on hand. As a leading 30 70 tin lead solder manufacturer, we prioritize customer satisfaction by delivering a product that meets the highest standards of durability and ease of use.

Our 30 70 lead solder comes with precise specifications tailored for optimal performance. The alloy composition is strictly Sn30 Pb70, meaning 30% tin and 70% lead, with impurities controlled to below 0.1%. The diameter is consistently 1.6mm, suitable for a wide range of soldering irons and machines. Each roll contains 500 grams of 30 70 lead solder 500g, providing substantial material for extended use. The lead solder Sn30 Pb70 is typically supplied on a sturdy spool with anti-tangle features, ensuring smooth unwinding during operation. As a professional 30 70 tin lead solder manufacturer, XF Solder includes flux-free options or can customize flux cores upon request. This attention to detail makes our tin solder Sn30 a preferred choice for professionals worldwide.

While lead solder Sn30 offers numerous benefits, it's essential to address safety and environmental aspects. Lead is a toxic material, so proper handling is crucial. Users should wear gloves and work in well-ventilated areas to avoid exposure. Disposal must comply with local regulations to prevent environmental contamination. As a responsible 30 70 tin lead solder manufacturer, XF Solder provides safety data sheets and guidelines for safe usage. We also encourage customers to explore lead-free alternatives if required by their industry standards. However, for applications where 30 70 tin solder is permissible, its performance advantages often outweigh the risks when managed correctly. The 30 70 lead solder 1.6mm diameter and 30 70 lead solder 500g roll are designed for efficient use, minimizing waste and potential hazards.

Choosing XF Solder as your 30 70 tin lead solder manufacturer means investing in quality and reliability. We implement strict quality control measures at every stage of production, from raw material selection to final packaging. Our tin solder Sn30 Pb70 is manufactured using high-purity metals and advanced extrusion technology, ensuring consistent diameter and alloy homogeneity. Each 30 70 lead solder roll is inspected for defects, guaranteeing that you receive a product that performs as expected. The 30 70 lead solder 1.6mm specification is maintained with tight tolerances, and the 30 70 lead solder 500g weight is accurately measured. By prioritizing quality, we help you achieve better soldering results with fewer rejects and rework.

As a Chinese 30 70 tin lead solder manufacturer, XF Solder offers significant advantages in terms of cost and scalability. Our location in a global manufacturing hub allows us to source materials efficiently and pass the savings on to our customers. This enables us to provide 30 70 lead solder at highly competitive prices without compromising on quality. We also have the capacity to handle large orders, making us an ideal partner for businesses with substantial sourcing needs. The tin solder Sn30 we produce meets international standards, and we offer flexible packaging options, including the popular 30 70 lead solder 500g roll. With a focus on customer service and timely delivery, XF Solder is your go-to source for reliable lead solder Sn30 Pb70.

In summary, the 30 70 Sn30 Pb70 Tin Lead Solder with a 1.6mm diameter in a 500g roll is a versatile, cost-effective solution for countless soldering applications. Its balanced composition as 30 70 lead solder ensures excellent performance in electronics, plumbing, and beyond. By sourcing from XF Solder, a reputable 30 70 tin lead solder manufacturer, you benefit from consistent quality, competitive pricing, and expert support. Whether you're looking for tin solder Sn30 for precision work or lead solder Sn30 Pb70 for heavy-duty joins, our product delivers on all fronts. Explore the advantages of this reliable solder today and experience the difference that professional-grade materials can make in your projects.

Contact us:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: 008613450770997

The selection of solder is a foundational element in the successful assembly and repair of LED lighting systems. The eutectic 63 37 sn pb solder offers an unparalleled combination of a low melting point, excellent wettability, and joint reliability that is perfectly suited to the thermal sensitivity of LED components. By understanding the specific applications for each diameter—from the precision of 63 37 sn pb solder 1.0mm to the power of 63 37 sn pb solder 2.0mm—you can dramatically improve the quality and efficiency of your work. Packaging this superior alloy as solder in a reel, specifically in a 63 37 sn pb solder 1 kg reel, adds layers of practicality, economy, and consistency that benefit everyone from the professional production engineer to the meticulous hobbyist. Therefore, equipping your workspace with the appropriate diameter of 63 37 sn pb solder for LED Lights is not just a purchase; it is an investment in achieving superior, reliable, and professional results in all you

Our comprehensive range of 63 37 leaded wire solder for electronics is meticulously designed to meet the exacting demands of modern electronics work. The eutectic 63/37 tin-lead alloy guarantees reliable, shiny joints free from cold solder defects. The availability of both 63 37 leaded solder 0.6mm for precision tasks and 63 37 leaded solder 0.9mm for versatile general-purpose work ensures you have the right tool for every job. Furthermore, our flexible packaging—from the bulk 63 37 leaded solder 454g for professionals, to the standard 63 37 leaded solder 227g, and the accessible 63 37 leaded solder 100g for beginners—means there is a perfect option for every user and budget. Elevate your soldering work with the proven performance and quality of genuine 63 37 leaded solder.

Welcome to XF Solder, a leading manufacturer from China dedicated to producing high-quality soldering materials for the global market. We specialize in creating reliable, consistent, and performance-driven solder products that meet the rigorous demands of various industries. Our flagship product, the 60 40 Solder .032'' 1 lb spool, represents the gold standard in through-hole and general-purpose electronics assembly. This article provides a detailed overview of why this specific formulation and packaging is an indispensable inventory item for distributors, a superior choice for importers seeking quality from China, and a perfect 60 40 Solder 1 lb for Wholesale operations globally. We will explore its technical specifications, unparalleled benefits, and the strategic advantage it offers in the competitive electronics supply chain.

The combination of the proven 60 sn 40 pb alloy, the convenience of three standard diameters (1.6mm, 1.8mm, 2mm), and the economic 1lb (454g) packaging makes this product an indispensable tool for anyone involved in creating or repairing electrical assemblies. Whether you are a seasoned engineer working on complex industrial systems or a hobbyist bringing your first circuit to life, this 60 40 sn pb wire solder provides the performance, reliability, and value you need to ensure every connection is perfect. Stock up on this classic soldering solution today and experience the difference that quality materials make.