| Tin Lead Solder Paste Sn60Pb40, comprised of 60% tin (Sn) and 40% lead (Pb), is a widely used soldering material in many applications. It is known as solder paste 60 40 too. This solder paste simplifies soldering processes while ensuring strong connections in various applications.

Sn60Pb40 solder paste is made of solder powder, flux, and binder. It plays a pivotal role in surface mount technology (SMT) and electronics assembly, enabling reliable solder connections. |

Alloy Composition | 60% Tin (Sn), 40% Lead (Pb) |

Melting Point | 183-190°C |

Flux Type | Rosin based flux |

Powder Size | Type 3 (25-45μm), Type 4 (20-38μm) |

Shelf Life | Recommended 6months |

Weight | 500g/jar |

Brand | XF Solder or OEM service |

*We also produce the solder paste in syringe. | |

Packing In Jars |

Packing In Syringe |

Lower Melting Point Sn60Pb40 solder paste typically has at 183°C to 190℃. It requires much lower heat than most other leaded solder paste alloy to work with. This characteristic makes it ideal for reflow soldering processes. | Good Wetting Property Solder paste 60 40 has excellent wetting properties, which means it can readily flow and bond with a variety of metal surfaces. It is compatible with a wide range of surface mount components, such as resistors, capacitors, integrated circuits (ICs), and more. | |

Reliable Solder Joints When properly applied, it creates strong solder joints with good electrical and thermal conductivity. This is crucial for the performance and longevity of electronic components and circuits. Also, it can provide reliable solder joints with good mechanical strength, making it suitable for many electronic applications. | Good Viscosity Sn60Pb40 solder paste is formulated to have a suitable viscosity for stencil printing during the soldering process. The viscosity can be adjusted by manufacturers to meet the requirements of different printing methods and equipment.

|

Solder paste 60 40 has been widely used in SMT assembly, creating dependable connections between components and PCBs. It's suitable for assembly of high precision soldering projects that use small IC components. We commonly see it in the manufacturing of consumer electronics and industrial electronics such as televisions, audio equipment, telecommunication devices etc.

Automatic Printing with Solder Paste |  Manual Printing with Solder Paste |

Jet Printing with Solder Paste |

Clean the PCB or soldering area properly to prepare it for putting solder paste on.

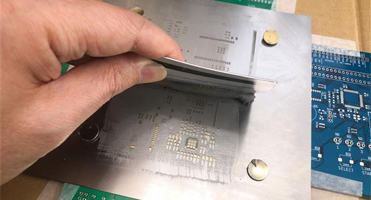

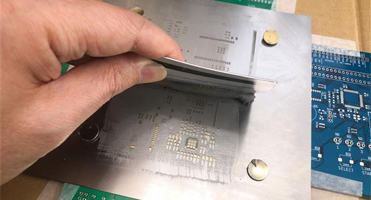

Place the stencil over the PCB, aligning it with the component footprints.

Apply proper amount of solder paste to the stencil by using a squeegee or automatic printing machine to spread the solder paste evenly across the stencil, filling the openings corresponding to the component pads.

Place SMD components on the PCB, aligning their pads with the solder paste.

Transfer the PCB with components into a reflow oven or appropriate soldering equipment.

Follow the recommended reflow profile to conduct the soldering process. This profile specifies the time and temperature settings for the solder paste to melt, reflow, and solidify.

It is recommended to store at 2°C to 10°C to prevent paste drying or degradation.

It's recommended to get the solder paste out of refrigerator 3 to 6 hours prior to using to get the paste come to the room temperature. Well mix the paste using a mixer machine or doing it manually by using spatula.

Un-finished solder paste must be well seal up again in the airtight jars to prevent contamination and moisture absorption, and put back into the refrigerator.

| Tin Lead Solder Paste Sn60Pb40, comprised of 60% tin (Sn) and 40% lead (Pb), is a widely used soldering material in many applications. It is known as solder paste 60 40 too. This solder paste simplifies soldering processes while ensuring strong connections in various applications.

Sn60Pb40 solder paste is made of solder powder, flux, and binder. It plays a pivotal role in surface mount technology (SMT) and electronics assembly, enabling reliable solder connections. |

Alloy Composition | 60% Tin (Sn), 40% Lead (Pb) |

Melting Point | 183-190°C |

Flux Type | Rosin based flux |

Powder Size | Type 3 (25-45μm), Type 4 (20-38μm) |

Shelf Life | Recommended 6months |

Weight | 500g/jar |

Brand | XF Solder or OEM service |

*We also produce the solder paste in syringe. | |

Packing In Jars |

Packing In Syringe |

Lower Melting Point Sn60Pb40 solder paste typically has at 183°C to 190℃. It requires much lower heat than most other leaded solder paste alloy to work with. This characteristic makes it ideal for reflow soldering processes. | Good Wetting Property Solder paste 60 40 has excellent wetting properties, which means it can readily flow and bond with a variety of metal surfaces. It is compatible with a wide range of surface mount components, such as resistors, capacitors, integrated circuits (ICs), and more. | |

Reliable Solder Joints When properly applied, it creates strong solder joints with good electrical and thermal conductivity. This is crucial for the performance and longevity of electronic components and circuits. Also, it can provide reliable solder joints with good mechanical strength, making it suitable for many electronic applications. | Good Viscosity Sn60Pb40 solder paste is formulated to have a suitable viscosity for stencil printing during the soldering process. The viscosity can be adjusted by manufacturers to meet the requirements of different printing methods and equipment.

|

Solder paste 60 40 has been widely used in SMT assembly, creating dependable connections between components and PCBs. It's suitable for assembly of high precision soldering projects that use small IC components. We commonly see it in the manufacturing of consumer electronics and industrial electronics such as televisions, audio equipment, telecommunication devices etc.

Automatic Printing with Solder Paste |  Manual Printing with Solder Paste |

Jet Printing with Solder Paste |

Clean the PCB or soldering area properly to prepare it for putting solder paste on.

Place the stencil over the PCB, aligning it with the component footprints.

Apply proper amount of solder paste to the stencil by using a squeegee or automatic printing machine to spread the solder paste evenly across the stencil, filling the openings corresponding to the component pads.

Place SMD components on the PCB, aligning their pads with the solder paste.

Transfer the PCB with components into a reflow oven or appropriate soldering equipment.

Follow the recommended reflow profile to conduct the soldering process. This profile specifies the time and temperature settings for the solder paste to melt, reflow, and solidify.

It is recommended to store at 2°C to 10°C to prevent paste drying or degradation.

It's recommended to get the solder paste out of refrigerator 3 to 6 hours prior to using to get the paste come to the room temperature. Well mix the paste using a mixer machine or doing it manually by using spatula.

Un-finished solder paste must be well seal up again in the airtight jars to prevent contamination and moisture absorption, and put back into the refrigerator.

The selection of solder is a foundational element in the successful assembly and repair of LED lighting systems. The eutectic 63 37 sn pb solder offers an unparalleled combination of a low melting point, excellent wettability, and joint reliability that is perfectly suited to the thermal sensitivity of LED components. By understanding the specific applications for each diameter—from the precision of 63 37 sn pb solder 1.0mm to the power of 63 37 sn pb solder 2.0mm—you can dramatically improve the quality and efficiency of your work. Packaging this superior alloy as solder in a reel, specifically in a 63 37 sn pb solder 1 kg reel, adds layers of practicality, economy, and consistency that benefit everyone from the professional production engineer to the meticulous hobbyist. Therefore, equipping your workspace with the appropriate diameter of 63 37 sn pb solder for LED Lights is not just a purchase; it is an investment in achieving superior, reliable, and professional results in all you

Our comprehensive range of 63 37 leaded wire solder for electronics is meticulously designed to meet the exacting demands of modern electronics work. The eutectic 63/37 tin-lead alloy guarantees reliable, shiny joints free from cold solder defects. The availability of both 63 37 leaded solder 0.6mm for precision tasks and 63 37 leaded solder 0.9mm for versatile general-purpose work ensures you have the right tool for every job. Furthermore, our flexible packaging—from the bulk 63 37 leaded solder 454g for professionals, to the standard 63 37 leaded solder 227g, and the accessible 63 37 leaded solder 100g for beginners—means there is a perfect option for every user and budget. Elevate your soldering work with the proven performance and quality of genuine 63 37 leaded solder.

Welcome to XF Solder, a leading manufacturer from China dedicated to producing high-quality soldering materials for the global market. We specialize in creating reliable, consistent, and performance-driven solder products that meet the rigorous demands of various industries. Our flagship product, the 60 40 Solder .032'' 1 lb spool, represents the gold standard in through-hole and general-purpose electronics assembly. This article provides a detailed overview of why this specific formulation and packaging is an indispensable inventory item for distributors, a superior choice for importers seeking quality from China, and a perfect 60 40 Solder 1 lb for Wholesale operations globally. We will explore its technical specifications, unparalleled benefits, and the strategic advantage it offers in the competitive electronics supply chain.

The combination of the proven 60 sn 40 pb alloy, the convenience of three standard diameters (1.6mm, 1.8mm, 2mm), and the economic 1lb (454g) packaging makes this product an indispensable tool for anyone involved in creating or repairing electrical assemblies. Whether you are a seasoned engineer working on complex industrial systems or a hobbyist bringing your first circuit to life, this 60 40 sn pb wire solder provides the performance, reliability, and value you need to ensure every connection is perfect. Stock up on this classic soldering solution today and experience the difference that quality materials make.