Views: 0 Author: Site Editor Publish Time: 2024-05-13 Origin: Site

In today's electronics manufacturing industry, Surface Mount Technology (SMT) has become mainstream. LED (Light Emitting Diode), as the main force of modern lighting and display technology, has extremely high requirements for high-quality SMT technology. As one of the key materials of SMT, leaded solder paste directly affects the quality and performance of electronic products. Leaded solder paste Sn63Pb37 is ideal for LED manufacturing with excellent performance and reliability. This article will introduce in detail the features, advantages and application of this product in LED manufacturing.

Tin Solder Paste Sn63Pb37 is a high quality SMT soldering material specially designed for LED manufacturing. Its main component is Sn63Pb37 alloy, containing 63% tin and 37% lead, as well as high-quality flux. T3 represents the solder powder specification in the tin solder paste is Type 3 (25 – 45 µm). This leaded solder paste performs well in LED manufacturing, ensuring soldering reliability, stability and consistency.

High-quality alloy: High-purity Sn63Pb37 alloy is used to ensure the reliability and stability of welding. This eutectic tin lead alloy has good electrical and thermal conductivity and is suitable for products such as LEDs that have strict requirements on electrical performance.

Excellent fluidity: The LED solder paste has good fluidity and can easily fill the gaps between SMT components to form uniform and strong solder joints. This helps improve welding quality and process stability.

Low oxidation rate: SMT tin solder paste has a low oxidation rate, which can stabilize welding at high temperatures, reduce solder joint oxidation and the formation of intermetallic compounds, and ensure the reliability and durability of welding.

T3 solder powder: This size of solder powder in this leaded solder paste, can meet the requirements of most conventional welding projects and is also affordable.

Tin solder paste Sn63Pb37 is widely used in LED manufacturing fields, including but not limited to the following applications:

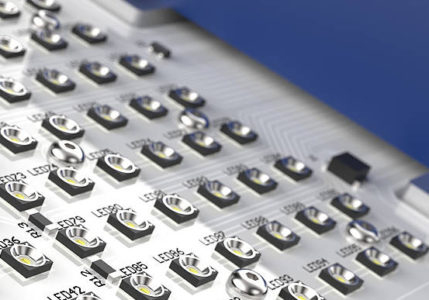

LED assembly: welding of LED chips and packaging substrates by using LED solder paste.

PCB assembly: using this STM tin solder paste forPCB assembly of LED lighting fixtures and displays.

Lamp bead assembly: using Sn63 solder paste to weld LED lamp beads and lamp circuit boards.

Preparation: Make sure the welding environment is well ventilated and wear appropriate protective equipment.

Prepare soldering equipment: Adjust the temperature and speed of the soldering equipment to ensure compliance with leaded solder paste requirements.

Apply tin solder paste: Use a squeegee or printer to evenly apply solder paste on the PCB.

Paste components: Paste SMT components on the location coated with smt tin solder paste.

Reflow soldering: Send the PCB into the reflow oven for soldering, ensuring that the solder paste sn63pb37 is completely melted and a uniform solder joint is formed.

Cleaning treatment: After welding is completed, perform necessary cleaning treatment to ensure that the welding point is clean and stable.

Precautions

During use, excessive heating should be avoided to prevent solder joints from oxidizing or burning the pads.

When welding, ensure that the welding equipment and environment meet safety requirements to avoid fire or other accidents.

Please read the product instructions carefully before use, and operate and store as required.

Conclusion

Leaded solder paste Sn63Pb37 provides LED manufacturers with high-quality soldering solutions due to its excellent performance and reliability. Whether in LED packaging, PCB assembly or lamp bead assembly, our products can meet your needs and provide guarantee for your product quality and stability. Choose T3 SMT, choose quality and reliability.

If you are looking for a China manufacturer of T3 SMT Leaded Tin Solder Paste Sn63Pb37 for LED Manufacturing, please contact us. Our WhatsApp/Wechat: 008613450770997 or Email: xfsolder@gmail.com or xfsolder@163.com