Views: 0 Author: Site Editor Publish Time: 2025-10-05 Origin: Site

In the intricate world of electronics and electrical repair, the quality of your materials is not just a detail—it's the foundation of a successful and durable connection. For professionals and hobbyists who demand reliability, the solder core wire alloy 40 60 stands as a benchmark for performance. This comprehensive guide delves into the specifics of a particularly popular format: the solder core wire 40 60 1mm 250g. We will explore its composition, unparalleled benefits, and the diverse applications that make it an indispensable tool in any electrical work toolkit. Understanding the properties of this specific solder core wire alloy 40 60 is the first step toward achieving flawless, high-strength solder joints every single time.

Before we examine the specific dimensions and weight, it's crucial to understand what the "40/60" designation means. This ratio refers to the alloy's composition, which is 40% tin and 60% lead. This classic formulation has been a cornerstone of electrical soldering for decades due to its unique set of characteristics that balance performance, cost, and ease of use.

The solder core wire alloy 40 60 is a eutectic-like alloy, though not a true eutectic. A true eutectic alloy, like 63/37 tin/lead, has a single melting point. The solder core wire 40 60, however, has a plastic range. It begins to melt at 183°C (361°F) and becomes fully liquid at 188°C (370°F). This 5-degree plastic range can be advantageous for certain applications, allowing the user a brief moment to adjust components before the solder fully solidifies. The 40% tin content provides excellent wetting properties, meaning it flows smoothly and adheres strongly to copper and other common metals. The 60% lead content contributes to the alloy's strength and lower melting point compared to higher-tin alternatives.

Choosing a solder core wire alloy 40 60 offers several distinct advantages. Its lower melting point reduces the risk of thermal damage to sensitive electronic components during the soldering process. The solder joint produced is strong, reliable, and has a characteristic shiny appearance when correctly executed. Furthermore, the solder core wire 40 60 is known for its excellent stability and resistance to oxidation during the soldering process, leading to cleaner joints and less wasted material. While lead-free alternatives are mandatory in some commercial applications, the solder core wire alloy 40 60 remains a top choice for many hobbyists, technicians, and in applications where its specific properties are required.

While the alloy composition is fundamental, the physical form of the solder is what makes it practical for daily use. The combination of a 1mm diameter and a 250g spool creates a product that is both highly versatile and conveniently packaged.

The solder 1mm diameter is often considered the workhorse of electronics soldering. This gauge is exceptionally versatile, making the solder core wire 1mm suitable for a wide array of tasks. It is substantial enough to deliver an adequate amount of solder quickly for medium-sized joints, such as those found on through-hole components, connector pins, and larger wires. At the same time, the solder 1mm wire is not so thick that it becomes difficult to control for more delicate work. This balance makes the solder core wire 40 60 1mm an excellent general-purpose choice for users who work on a variety of projects and don't want to switch between different spools constantly.

The solder 250g spool represents the ideal balance between quantity and manageability. A 250-gram spool of solder core wire 250g provides a substantial amount of material, ensuring that you won't run out mid-project during extensive repair sessions or production runs. It is a cost-effective size for regular users, offering better value per gram than smaller, consumer-grade spools. Furthermore, the solder 250g package is compact and fits perfectly on most standard soldering stations' integrated spool holders, keeping your workspace organized. The solder core wire 40 60 250g is a professional-grade quantity that signifies a commitment to quality and efficiency.

When you purchase a spool of solder core wire 40 60 1mm 250g, you are investing in a product designed for excellence. Here are the key features that set it apart:

A critical component of any solder core wire is the flux within. Our solder core wire 1mm is engineered with a precision-formulated rosin flux core. This flux is activated by heat and serves multiple purposes: it cleans the metal surfaces of oxides, prevents re-oxidation during soldering, and significantly improves the flow and wetting of the molten solder core wire alloy 40 60. The result is a clean, strong, and reliable connection without the need for additional flux in most standard applications.

Consistency is king in professional electrical work. Every meter of the solder core wire 40 60 1mm is manufactured to strict tolerances, ensuring a uniform diameter and a consistent alloy mixture. This means the melting behavior and flow characteristics are predictable every time you use it. You can trust that the solder core wire 40 60 250g will perform identically from the start of the spool to the very end, eliminating variables that can lead to faulty solder joints.

Thanks to the specific solder core wire alloy 40 60 composition, this product exhibits superior wetting action. The molten solder effortlessly spreads across component leads and PCB pads, creating a concave fillet that is both electrically sound and mechanically robust. The solder core wire 40 60 1mm 250g is designed to create perfect joints with a smooth, shiny finish, which is a visual indicator of a good solder connection.

The versatility of the solder core wire 40 60 1mm 250g makes it suitable for a vast spectrum of electrical and electronic tasks.

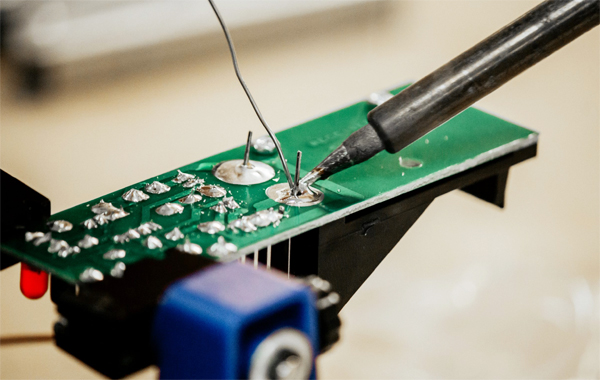

This is the primary domain for the solder core wire 1mm. It is perfectly suited for soldering through-hole components like resistors, capacitors, and ICs onto printed circuit boards (PCBs). The solder core wire 40 60 1mm provides the right amount of material for strong, reliable connections on standard PCB pads.

Beyond circuit boards, the solder core wire 40 60 250g is excellent for general electrical work. It is ideal for tinning stranded copper wires before inserting them into terminals, creating strong splices, and repairing connections in appliances, automotive wiring, and other electrical devices. The strength of the solder 40 60 1mm 250g alloy ensures these connections can withstand vibration and stress.

For the maker and DIY enthusiast, having a reliable spool of solder core wire 40 60 1mm 250g is essential. Whether you're building a robot, repairing a guitar cable, or creating custom LED lighting, this solder provides the professional-grade results that hobbyists crave. Its ease of use and consistent performance make complex projects more manageable and successful.

To get the most out of your solder core wire 40 60 1mm 250g, proper technique is essential.

Preparation: Ensure all surfaces are clean. Use a sponge or brass wool to clean the tip of your soldering iron.

Heating: Apply the tip of the soldering iron to both the component lead and the PCB pad simultaneously. The goal is to heat the metals, not just the solder itself.

Applying Solder: After 1-2 seconds, touch the solder core wire 40 60 1mm to the junction of the heated component and pad. The flux will boil away, and the solder will melt and flow smoothly.

Completion: Remove the solder wire first, then the iron. Allow the joint to cool naturally without movement. A good joint will be smooth, shiny, and concave.

Always work in a well-ventilated area, as soldering fumes can be irritating. Use safety glasses to protect your eyes from potential splatter. Be mindful of the hot iron and freshly soldered joints, as they can cause severe burns. After using your solder core wire 250g, store it in a cool, dry place to maintain its quality.

In summary, the solder core wire 40 60 1mm 250g is a meticulously engineered product that combines the proven performance of a 40/60 tin/lead alloy with the practical convenience of a 1mm diameter and a 250-gram spool. Its excellent wetting properties, consistent performance, and robust flux core make the solder core wire alloy 40 60 an unbeatable choice for a wide range of electrical and electronic applications. From professional PCB assembly to weekend DIY projects, this specific format—the solder 40 60 1mm 250g—delivers the reliability, strength, and ease of use that professionals and enthusiasts rely on. Equip your workspace with this high-quality solder core wire 40 60 250g and experience the difference that a premium material makes.

Contact us:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: 00861345070997