Views: 0 Author: Site Editor Publish Time: 2025-06-27 Origin: Site

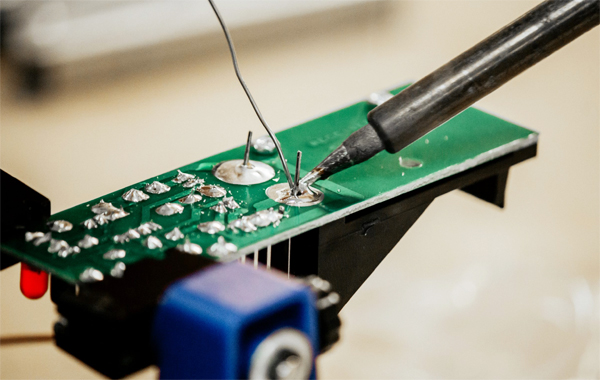

When it comes to soldering electronic components, choosing the right solder wire is crucial for achieving strong, reliable connections. Rosin solder 60% tin (Sn) and 40% lead (Pb) is a popular choice among professionals and hobbyists for its excellent flow characteristics and durability. This solder wire, available in a 0.9mm diameter and 250gm spool, is specifically designed for circuit boards soldering, ensuring smooth and efficient electrical connections.

In this article, we’ll explore the benefits of using rosin solder 60% Sn 40% Pb, its ideal applications, and why this formulation is preferred for electronics work.

Rosin solder is a type of solder wire that contains a flux core made from rosin, a natural resin derived from pine trees. The flux helps remove oxidation from metal surfaces, ensuring a clean and strong bond. The rosin solder 60% tin 40% lead composition is widely used because it offers an optimal balance between melting temperature, electrical conductivity, and mechanical strength.

Excellent Electrical Conductivity – The 60% tin (Sn) and 40% lead (Pb) ratio ensures low resistance, making it ideal for circuit boards soldering.

Superior Wetting Properties – The rosin flux core promotes better adhesion to copper traces and component leads.

Reliable Melting Point – This alloy melts at around 183-190°C (361-374°F), making it easy to work with using standard soldering irons.

Strong Mechanical Bonds – The rosin solder 60% Sn 40% Pb creates durable joints that resist vibration and thermal stress.

The rosin solder for circuit boards is widely used in:

PCB Assembly – Perfect for through-hole and surface-mount component soldering.

Electronics Repair – Ideal for fixing broken traces or replacing faulty components.

DIY Electronics Projects – A great choice for hobbyists building custom circuits.

Industrial Manufacturing – Used in mass production of electronic devices due to its reliability.

The 0.9mm diameter of this solder wire makes it suitable for both fine-pitch soldering and general-purpose connections. The 250gm spool provides ample length for multiple projects without frequent replacements.

The rosin solder 60% Sn 0.9mm variant offers several benefits:

Precision Control – The thin diameter allows for accurate application, reducing the risk of solder bridges.

Efficient Flux Distribution – The rosin core ensures consistent flux release, preventing cold joints.

Versatility – Works well with small SMD components as well as larger connections.

For those working on intricate PCB designs, the rosin solder 60% Sn 250gm spool ensures a steady supply of high-quality solder wire.

The rosin flux in rosin solder for circuit boards plays a critical role in:

Removing Oxidation – Ensures clean metal surfaces for better solder adhesion.

Preventing Corrosion – Protects joints from environmental damage.

Reducing Solder Balls & Splatter – Promotes smooth, clean solder flow.

Unlike acid-core fluxes, rosin flux is non-corrosive, making it safe for delicate electronic components.

While lead-free solders are gaining popularity due to environmental regulations, rosin solder 60% tin 40% lead remains a top choice for its superior performance:

| Feature | 60/40 Rosin Solder | Lead-Free Solder |

|---|---|---|

| Melting Point | 183-190°C | 217-227°C |

| Wetting Ability | Excellent | Moderate |

| Joint Strength | High | Lower |

| Workability | Easy | Requires higher heat |

For precision work, the rosin solder 60% Sn 40% Pb offers better ease of use and reliability.

Prepare the Soldering Iron – Set the temperature to 300-350°C (572-662°F) for optimal performance.

Clean the PCB & Components – Remove dirt or oxidation using isopropyl alcohol.

Apply the Solder – Touch the rosin solder 60% Sn 0.9mm wire to the joint and allow it to flow smoothly.

Inspect the Joint – A good solder joint should be shiny and smooth, not dull or lumpy.

Using a 250gm spool ensures you have enough solder for multiple projects without frequent reordering.

While rosin solder 60% tin 40% lead is highly effective, lead exposure can be hazardous. Follow these precautions:

Work in a Well-Ventilated Area – Avoid inhaling fumes.

Wash Hands After Use – Prevent lead contamination.

Use a Fume Extractor – Recommended for prolonged soldering sessions.

If you're looking for reliable rosin solder for circuit boards, ensure you purchase from trusted suppliers. The rosin solder 60% Sn 250gm spool in 0.9mm diameter is widely available from electronics distributors.

For professionals and hobbyists working on circuit boards soldering, the rosin solder 60% tin (Sn) and 40% lead (Pb) in 0.9mm diameter and 250gm spool is an excellent choice. Its superior wetting properties, strong mechanical bonds, and ease of use make it a staple in electronics manufacturing and repair.

Whether you're assembling a new PCB or repairing an old device, this rosin solder 60% Sn 40% Pb ensures reliable, long-lasting connections. Stock up on a 250gm spool today and experience the difference in your soldering projects!

By incorporating the right rosin solder into your workflow, you can achieve clean, efficient, and durable solder joints every time. Choose rosin solder 60% tin 40% lead for the best results in circuit boards soldering!

Contact Information:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: +8613450770997