Views: 0 Author: Site Editor Publish Time: 2025-06-24 Origin: Site

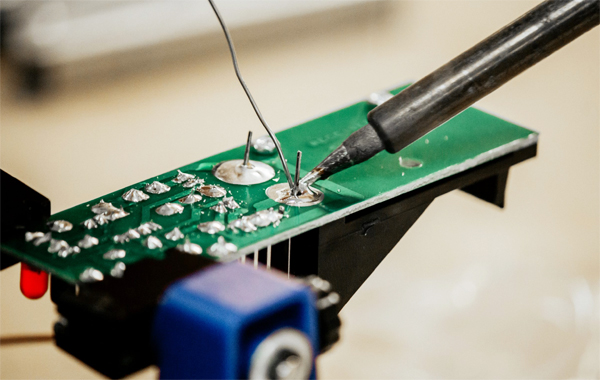

When it comes to PCB welding, selecting the right solder is crucial for ensuring strong, reliable connections. Among the various options available, Sn/Pb Solder 30/70 (30% tin and 70% lead) remains a popular choice for many electronics professionals. This 1.8mm 100g/reel Sn/Pb Solder offers excellent workability, strong bonding, and cost-effectiveness, making it ideal for both hobbyists and industrial applications.

In this article, we will explore the benefits, applications, and key features of Pb Solder 30/70 and Sn Solder 30/70, focusing on why this alloy is widely used in PCB welding.

Sn/Pb Solder 30/70 is a lead-based solder alloy composed of 30% tin (Sn) and 70% lead (Pb). This combination provides a lower melting point compared to higher tin-content solders, making it easier to work with in various PCB welding applications.

The 1.8mm diameter of this solder wire makes it suitable for medium to large soldering tasks, while the 100g reel ensures convenient handling and storage.

Excellent wetting properties – Ensures smooth flow and strong adhesion to PCB components.

Lower melting point – Reduces thermal stress on sensitive electronic parts.

Cost-effective – More affordable than high-tin or lead-free alternatives.

Durable joints – Provides long-lasting electrical and mechanical connections.

Despite the rise of lead-free alternatives, Pb Solder for PCB welding remains widely used due to its superior performance in certain applications. Here’s why many professionals still prefer Sn/Pb Solder 30/70:

Pb Solder 30/70 has excellent flow characteristics, making it easier to create smooth, shiny solder joints. This is particularly beneficial for manual soldering tasks where precision is key.

Compared to Sn-rich solders, Sn/Pb Solder 30/70 melts at a lower temperature (around 260°C). This reduces the risk of damaging heat-sensitive PCB components.

The 70% lead content in Pb Solder for PCB enhances mechanical strength, making it ideal for applications where durability is critical.

Since lead is cheaper than tin, Sn/Pb Solder 30/70 is a more economical option for large-scale manufacturing.

This 1.8mm 100g/reel Sn/Pb Solder is widely used in various electronics and PCB welding tasks, including:

The 30/70 tin-lead ratio provides excellent hole-filling capabilities, making it perfect for through-hole PCB assembly.

Due to its smooth flow and lower melting point, Sn Solder for PCB welding is ideal for manual repairs and touch-ups.

Many manufacturers still rely on Pb Solder 30/70 for its reliability in high-volume production.

While lead-free solders are becoming more common, some high-reliability industries still use Sn/Pb Solder for PCB due to its proven performance under stress.

Sn60/Pb40 has a higher tin content, resulting in a slightly higher melting point.

Sn/Pb Solder 30/70 is more cost-effective and better suited for applications where lead’s mechanical strength is needed.

Lead-free solders (e.g., SAC305) are environmentally friendly but require higher temperatures.

Pb Solder for PCB welding offers easier handling and better joint reliability in some cases.

To achieve optimal results with Sn/Pb Solder for PCB welding, follow these tips:

Use a Suitable Soldering Iron – A temperature-controlled iron set between 400-450°C works best.

Apply Flux if Needed – While this solder contains flux, additional flux may help with oxidation-prone surfaces.

Ensure Proper Ventilation – Lead-based solders should be used in well-ventilated areas to avoid fume inhalation.

Store Properly – Keep the 100g reel in a dry place to prevent oxidation.

Since Pb Solder 30/70 contains lead, it is important to handle it responsibly:

Wear gloves to avoid direct skin contact.

Work in a ventilated area to minimize exposure to fumes.

Dispose of waste properly according to local regulations.

While lead-free solders are becoming more common, Sn/Pb Solder for PCB welding remains a practical choice where performance outweighs environmental concerns.

The 1.8mm 100g/reel Sn/Pb Solder 30/70 is an excellent choice for PCB welding, offering a balance of affordability, workability, and reliability. Whether you're working on DIY projects or industrial electronics, this Pb Solder for PCB provides strong, durable connections with ease.

For those who prioritize performance and cost-efficiency, Sn/Pb Solder 30/70 remains a top contender in the world of electronics soldering.

Contact Information:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: +8613450770997