Views: 0 Author: Site Editor Publish Time: 2025-06-20 Origin: Site

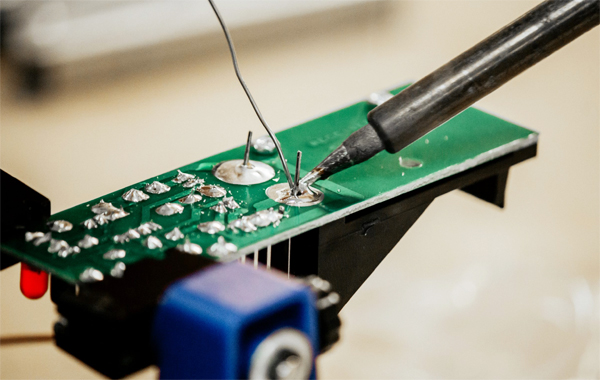

When it comes to assembling SMD components, selecting the right solder is crucial for ensuring strong, reliable connections. The 1.6mm diameter 60 tin 40 lead resin cored solder is an excellent choice for professionals and hobbyists alike. This solder wire combines the benefits of 60/40 tin-lead alloy with a resin core flux, making it ideal for precision soldering tasks.

In this detailed product guide, we’ll explore why 60 tin 40 lead solder for SMD components is a top pick for electronics assembly, its key features, and how it compares to other soldering options.

The 60 tin 40 lead solder blend is one of the most widely used alloys in electronics. The 60% tin and 40% lead ratio ensures:

Low melting point (183°C - 190°C) for easy application

Excellent wetting properties for strong solder joints

Reduced risk of cold solder joints compared to lead-free alternatives

The resin cored solder 1.6mm variant includes an embedded flux that:

Removes oxidation from metal surfaces

Improves solder flow for smooth joints

Minimizes the need for additional flux

The 60 tin 40 lead solder for SMD components is particularly effective because:

The 1.6mm diameter provides controlled solder deposition

The flux core ensures clean, void-free connections on tiny SMD pads

It reduces bridging and solder balling, common issues in SMD soldering

The 60 40 solder 1.6mm thickness is perfect for:

Hand soldering of SMD resistors, capacitors, and ICs

Rework and repair jobs requiring precision

PCB prototyping where controlled solder application is essential

Unlike cheaper alternatives, this resin cored solder 1.6mm uses a no-clean flux that:

Leaves minimal residue

Does not require post-soldering cleaning in most cases

Prevents corrosion on sensitive components

The tin lead solder 60 40 1.6mm ensures:

Low resistance connections for optimal circuit performance

Strong mechanical bonds that withstand vibrations and thermal stress

This tin lead solder for SMD is widely used in:

Consumer electronics manufacturing (smartphones, laptops, TVs)

Automotive electronics (ECUs, sensors, infotainment systems)

Industrial PCB assembly (control boards, power supplies)

Hobbyist projects (Arduino, Raspberry Pi, DIY circuits)

| Feature | 60 Tin 40 Lead Solder 1.6mm | Lead-Free Solder (SAC305) |

|---|---|---|

| Melting Point | 183°C - 190°C | 217°C - 227°C |

| Wetting Ability | Excellent | Good (requires higher temp) |

| Flux Core | Resin (no-clean) | Often more aggressive flux |

| Solder Joint Strength | High | Moderate (more brittle) |

| Cost | Affordable | More expensive |

For SMD soldering, the tin lead solder 1.6mm is often preferred due to its easier handling and superior joint reliability.

Pre-tin the iron tip for better heat transfer

Apply solder to the joint, not the iron, for even distribution

Use the right temperature (300°C - 350°C) to avoid overheating

Keep the 60 tin 40 lead resin cored solder in a dry place

Avoid exposure to moisture to prevent flux degradation

Work in a well-ventilated area (flux fumes can be irritating)

Use lead-safe handling practices if required by regulations

A: While 60 tin 40 lead solder has a lower melting point than lead-free options, it is suitable for most consumer and industrial electronics. For extreme heat environments, high-lead or specialty solders may be needed.

A: Yes! The 1.6mm 60 40 solder works well for both SMD and through-hole soldering.

A: The resin cored solder 1.6mm uses a no-clean flux, meaning residue is minimal and non-corrosive. However, for critical applications, a quick IPA wipe may be used.

For professionals and enthusiasts working with SMD components, the 1.6mm diameter 60 tin 40 lead resin cored solder offers unmatched performance. Its optimal alloy composition, high-quality flux core, and precise diameter make it a top choice for reliable, clean, and efficient soldering.

Whether you're assembling PCBs, repairing electronics, or working on DIY projects, this tin lead solder for SMD 1.6mm ensures strong, long-lasting connections every time.

Order your 60/40 resin cored solder today and experience superior soldering performance!

Contact Information:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: +8613450770997