Views: 0 Author: Site Editor Publish Time: 2025-10-10 Origin: Site

In the intricate world of electronics assembly and repair, the choice of solder is not merely a detail—it's a foundational decision that impacts the quality, reliability, and efficiency of your work. For countless professionals and hobbyists, the consistent performance of a specific type of solder stands out: the .032 lead solder 60 40. This comprehensive guide delves deep into why this particular electronic solder, especially in its convenient .032 solder 60 40 1 lb roll format, remains an indispensable tool in workshops and production lines worldwide. We will explore its composition, unique benefits, and the specific applications where it excels, providing you with all the knowledge needed to make an informed decision for your next project.

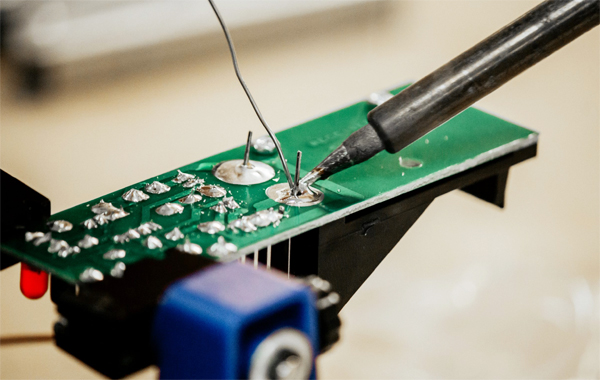

Before we focus on the specific advantages of .032 solder 60 40, it's crucial to understand the fundamental category it belongs to: lead solder. For decades, soldering has been the primary method for creating permanent, conductive bonds between electronic components and circuit boards. Traditional solder is a metal alloy designed to melt at a lower temperature than the pieces being joined. The classic and most widely recognized formulation is the tin-lead alloy. The inclusion of lead significantly lowers the melting point of the alloy compared to pure tin, making it easier to work with and creating highly reliable, strong joints with excellent wetting properties. While lead-free alternatives have gained prominence due to environmental regulations, lead solder continues to be praised for its superior workability and the unparalleled quality of the connections it forms, particularly in non-commercial and specific industrial applications.

The numbers "60" and "40" in lead solder 60 40 are not arbitrary; they represent the precise alloy composition by weight. This specific blend consists of 60% tin and 40% lead. This ratio is a time-tested formula that strikes a perfect balance in soldering performance. The 60% tin content is responsible for the solder's ability to wet and adhere to component leads and PCB pads effectively, ensuring a strong bond. The 40% lead content is what gives the alloy its desirable mechanical strength and, most importantly, creates a "eutectic" or near-eutectic point. A eutectic alloy has a single, sharp melting point rather than a plastic range. While pure 63/37 solder is truly eutectic, lead solder 60 40 is so close that it behaves similarly, transitioning from solid to liquid almost instantly at around 188°C (370°F). This characteristic is critical as it prevents "cold solder joints," a common defect caused by disturbed movement during the paste-like phase of non-eutectic alloys.

The diameter of solder wire is a critical, yet often overlooked, specification. The .032 solder 60 40 refers to a wire that is 0.032 inches (or approximately 0.81 millimeters) in diameter. This size is widely regarded as the gold standard for a vast range of through-hole and larger surface-mount soldering tasks. Its popularity stems from its versatility. A thinner diameter might feed too quickly or require frequent reloading for larger joints, while a thicker one could deliver too much solder, leading to blobs, bridges, and potential shorts. The .032 lead solder 60 40 provides the perfect balance, allowing for controlled application and excellent flow characteristics. It is the ideal choice for soldering standard component leads, wires, connectors, and many other common electronic elements, making a roll of .032 solder 60 40 1 lb a perfect all-purpose stock for any electronics bench.

When we narrow our focus to electronic solder 60 40, we are highlighting a product engineered specifically for the delicate and precise world of electronics. General-purpose solders may contain different fluxes or impurities unsuitable for circuit boards. In contrast, high-quality electronic lead solder is manufactured to stringent standards to ensure it does not introduce contaminants that could corrode components or degrade performance over time. The core of this solder wire is filled with a flux, typically rosin-based. This flux is essential as it cleans the metal surfaces of oxides during the soldering process, allowing the molten solder to form a perfect metallurgical bond. The performance of electronic solder 60 40 is characterized by its smooth flow, bright, shiny joint finish, and the creation of strong, conductive, and reliable connections that are vital for the long-term health of any electronic device.

Investing in a .032 lead solder 60 40 1 lb roll offers a combination of practical benefits that directly translate to better workflow and higher quality results. Let's break down the key advantages of this specific product configuration.

The primary reason for the enduring popularity of .032 lead solder 60 40 is the exceptional quality of the solder joints it produces. The near-eutectic nature of the 60/40 alloy means it solidifies quickly once the heat is removed, minimizing the risk of fractured or disturbed joints. The resulting connections are strong, both mechanically and electrically, and have a characteristically bright, shiny appearance that is a visual indicator of a good solder joint. The .032 diameter allows for precise control over the amount of solder dispensed, enabling you to create perfect, concave fillets on through-hole components without causing bridges on fine-pitch parts. This superior workability makes electronic lead solder of this type a favorite for rework and repair, where precision is paramount.

Purchasing your solder in a .032 solder 60 40 1 lb roll is a decision that balances economy with practicality. For frequent users, buying in bulk is far more cost-effective than purchasing small, 1-ounce spools. A lead solder 60 40 1 lb roll provides a substantial amount of material, reducing the frequency of reorders and ensuring you never run out in the middle of an important project. Furthermore, the standard 1 lb spool is designed to fit perfectly on most common soldering station holders, allowing for smooth, uninterrupted wire feeding as you work. The convenience of having a dedicated, substantial roll of .032 lead solder 60 40 1 lb at your workstation streamlines the entire soldering process, enhancing overall productivity.

Not all soldering tasks are created equal. Some applications, such as in automotive, aerospace, or high-value audio equipment, demand the highest levels of reliability. The proven track record of .032 lead solder 60 40 in these fields is a testament to its performance. The alloy's excellent thermal fatigue resistance means it can withstand the expansion and contraction cycles that occur with temperature changes, preventing joint failure over time. When you use a high-grade electronic solder 60 40, you are using a material that has been trusted for decades to create connections that last, making it a reliable choice for both prototyping and end-product manufacturing where failure is not an option.

With various options available, selecting the right solder can seem daunting. However, by focusing on your specific application, the choice becomes clear.

The .032 electronic lead solder is your ideal candidate for the majority of through-hole technology (THT) work. This includes building and repairing circuit boards for amplifiers, power supplies, microcontroller projects like Arduino and Raspberry Pi, and vintage electronics restoration. If your work involves soldering wires to terminals, connectors, or switches, the .032 diameter provides the perfect volume of solder for a robust connection. Essentially, if you are not exclusively working with ultra-fine-pitch surface-mount devices (SMDs), a roll of .032 lead solder 60 40 1 lb should be your default choice. It is the versatile workhorse that can handle probably 80% of all electronic soldering tasks with ease and excellence.

It is an inescapable responsibility to address the health and environmental considerations associated with lead solder. Lead is a toxic heavy metal, and exposure can be harmful. When working with any electronic solder 60 40 containing lead, it is imperative to follow strict safety protocols:

Adequate Ventilation: Always work in a well-ventilated area. Use a fume extractor or fan to draw the flux smoke away from your breathing zone. While the primary hazard is the lead itself, the flux fumes can be an irritant.

Personal Hygiene: Wash your hands thoroughly with soap and water after handling solder or soldered boards, and especially before eating or drinking.

Workspace Management: Keep your work area clean to prevent the accumulation of lead-containing dust or debris.

Always be aware of and comply with local regulations, such as the RoHS (Restriction of Hazardous Substances) directive, which restricts the use of lead in commercial electronic products in many regions. For commercial products, lead-free solder is often mandated by law, but for hobbyist, repair, and certain exempted industries, lead solder 60 40 remains a legal and highly effective option when used responsibly.

In the landscape of electronic assembly, trends come and go, but the fundamental principles of creating a reliable connection remain. The .032 lead solder 60 40 1 lb roll embodies these principles. Its optimal diameter, superior near-eutectic alloy composition, and proven performance make it an unparalleled choice for a vast spectrum of soldering tasks. From the hobbyist building a first kit to the seasoned technician performing critical repairs, this electronic lead solder delivers consistent, high-quality results that few other products can match. By choosing a high-quality .032 solder 60 40, you are not just selecting a material; you are investing in the reliability, durability, and success of your electronic creations. Ensure you source your materials from reputable suppliers to guarantee purity and performance, and always prioritize safety in your workspace.

Contact us:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: 008613450770997