Views: 0 Author: Site Editor Publish Time: 2025-09-17 Origin: Site

In the world of electronics assembly, the quality of your solder can make or break your project. Whether you're a professional technician or a passionate hobbyist, having the right soldering materials is crucial for creating strong, reliable connections. One product that stands out in this regard is the 0.8mm Sn60 60 40 rosin core solder wire supplied in a convenient 200grams spool. This specific formulation, often referred to as solder sn60, is a top choice for countless electronics experts. In this comprehensive guide, we will explore everything you need to know about this exceptional soldering wire and why it should be a staple in your toolkit.

Before diving into the specifics of the 0.8mm diameter and the 200-gram spool, it's important to understand the base material. 60 40 rosin core solder for electronics is one of the most common and widely used types of solder. The numbers "60/40" represent the alloy composition: 60% tin (Sn) and 40% lead (Pb). This combination creates a eutectic alloy, meaning it has a single, sharp melting point, which is lower than that of either pure tin or pure lead. This property is incredibly beneficial for soldering, as it allows the alloy to melt and solidify quickly, minimizing the risk of cold joints.

The "rosin core" refers to the flux located at the center of the solder wire. This flux is a specially formulated material that serves a critical purpose. As you apply heat during soldering, oxidation occurs on the metal surfaces of your components and PCB pads. This oxide layer prevents proper adhesion of the solder. The rosin core flux actively cleans these surfaces, removing oxidation and ensuring a clean, solid bond between the solder and the metals. Using a 60 40 rosin core solder wire ensures this cleaning process happens automatically from within the wire itself, streamlining your workflow.

Sn60 is a standard designation for this 60/40 tin-lead alloy. While lead-free alternatives have gained popularity due to environmental regulations (like RoHS), solder sn60 remains highly valued for several reasons, especially in applications where such regulations do not apply, such as in prototyping, automotive repairs, or certain aerospace and military applications.

The primary advantages of sn60 solder are its excellent wettability and ease of use. Its eutectic nature means it transitions from liquid to solid almost instantly at around 188°C (370°F), which greatly reduces the chance of disturbing the joint as it cools. This results in shiny, smooth, and reliable connections with high mechanical strength. For those new to soldering, 60 40 rosin core solder for electronics is often easier to work with than lead-free options, which typically have higher melting points and can be less forgiving.

The diameter of your solder wire is not a trivial detail; it directly impacts the precision and quality of your work. The 0.8mm diameter of this 60 40 rosin core solder 0.8mm wire makes it an incredibly versatile choice. It is perfectly suited for a wide range of tasks in electronics assembly.

For through-hole components (THT), which have leads that are inserted into holes on a PCB, the 0.8mm size allows you to apply a sufficient amount of solder quickly without making a mess. It's thick enough to fill joints efficiently but not so thick that it becomes difficult to control. For larger surface-mount technology (SMT) components or for tinning wires, this diameter provides excellent control and a good feed rate. It strikes a ideal balance, making it a fantastic general-purpose size that both beginners and experts can use effectively for most common tasks without needing to switch between different spools.

Productivity in any workshop is about efficiency, and having your materials well-organized is a key part of that. This solder comes packaged in a practical 200grams spool. This size is substantial enough to last through numerous projects, reducing the frequency of reorders and ensuring you always have solder on hand. At the same time, it remains a manageable size that is easy to store and handle on your workbench without being overly bulky or heavy.

The spool itself is designed for functionality. It allows the 60 40 rosin core solder in spool to be fed out smoothly without tangling or kinking. The spool often includes a handy tab to secure the loose end of the wire, preventing unwinding and keeping your workspace tidy. The concept of solder in spool or solder wire in spool is the industry standard for a reason: it provides superior protection for the product and unparalleled convenience for the user compared to loose coils.

The combination of its alloy, flux, diameter, and packaging makes this product exceptionally well-suited for electronics work. Here’s how you can use this 60 40 rosin core solder wire effectively:

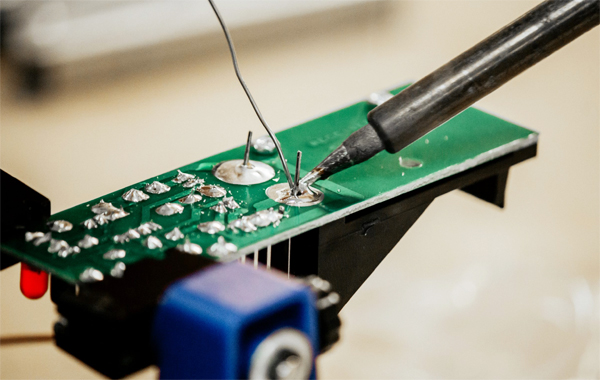

PCB Repair and Rework: The controlled feed of the 0.8mm wire from the solder wire in spool is perfect for adding components or repairing broken traces on printed circuit boards.

Through-Hole Soldering: This is where 60 40 rosin core solder for electronics truly shines. The rosin core flux ensures strong, reliable connections for resistors, capacitors, connectors, and other through-hole components.

Tinning Wires: Before connecting wires to terminals, it is good practice to "tin" them—coat the stranded ends with a layer of solder. This solder sn60 product is ideal for this, preventing fraying and ensuring a better connection.

General Hobbyist Projects: From building Arduino kits to repairing guitar cables, this versatile solder is a must-have for any DIY electronics enthusiast.

To get the most out of your 60 40 rosin core solder 200grams spool, follow these tips:

Clean Your Iron: Always keep your soldering iron tip clean and well-tinned. Wipe it frequently on a damp sponge or brass wire sponge.

Apply Heat Correctly: Heat the joint, not the solder. Touch the tip of the iron to both the component lead and the PCB pad simultaneously. After a second or two, feed the 0.8mm solder wire into the joint—it should flow smoothly onto the heated surfaces.

Let the Flux Work: The rosin core 60 40 flux will activate and bubble away as it cleans. You don't typically need additional flux for most standard electronics applications.

Avoid Overheating: Apply heat only for as long as necessary to melt the solder and create a good joint. Overheating can damage components and the PCB itself, and it can break down the flux too quickly, reducing its effectiveness.

Store Properly: Keep your solder in spool in a cool, dry place to maintain its performance over time.

In summary, the 0.8mm Sn60 60 40 Rosin Core Solder Wire in 200grams Spool is a premium, all-purpose solution for anyone involved in electronics assembly and repair. The proven sn60 eutectic alloy ensures strong, reliable joints with a smooth finish. The integrated rosin flux core guarantees excellent cleanliness and connectivity without the need for a separate flux application. The 0.8mm diameter offers superb control for a vast array of tasks, from delicate SMT work to heavier through-hole soldering. Finally, the practical 200grams spool provides great value and convenience, keeping your workspace organized and your projects moving forward smoothly.

Equip yourself with this high-quality 60 40 rosin core solder in spool and experience the difference that the right materials can make in the quality and efficiency of your electronic work.

Contact us:

Email: xfsolder@gmail.com or xfsolder@163.com

WhatsApp/Wechat: 008613450770997