Views: 0 Author: Site Editor Publish Time: 2025-06-21 Origin: Site

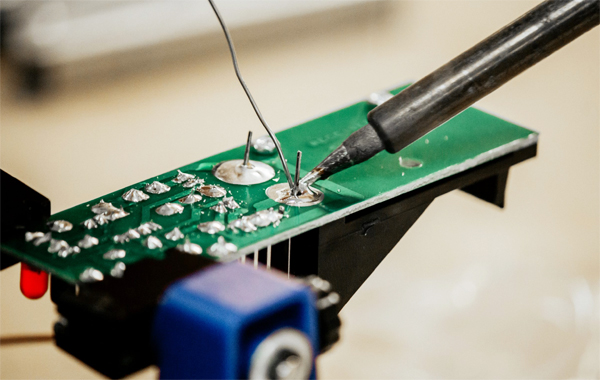

In the world of electronics manufacturing, precision and reliability are paramount. One of the most critical components in PCB assembly and repair is solder wire with flux rosin core, particularly the solder wire 63/37 with flux rosin core (Sn63Pb37). This alloy composition ensures a eutectic melt point, making it ideal for high-quality soldering applications.

This comprehensive guide explores the different diameters of solder wire Sn63Pb37 with flux rosin core, including 0.8mm solder wire with flux rosin core, 1mm solder wire with flux rosin core, 1.2mm solder wire with flux rosin core, 1.6mm solder wire with flux rosin core, 2mm solder wire with flux rosin core, and 3mm solder wire with flux rosin core. We’ll discuss their applications, benefits, and why they are essential for solder wire with flux rosin core for electronics manufacturing.

Solder wire with flux rosin core is a specialized soldering material consisting of a metal alloy (typically Sn63Pb37) with an embedded flux core. The flux, usually rosin-based, removes oxidation, prevents re-oxidation, and enhances wetting for strong, reliable solder joints.

The solder wire 63/37 with flux rosin core is particularly popular due to its eutectic properties—melting at a single temperature (183°C/361°F) rather than a range, ensuring smooth, void-free connections.

The solder wire Sn63Pb37 with flux rosin core offers several advantages:

Eutectic Alloy: Ensures a quick transition from solid to liquid, reducing the risk of cold joints.

Excellent Wetting: The flux rosin core promotes superior adhesion to copper, brass, and other metals.

Minimal Splatter: Provides clean, controlled soldering with minimal waste.

Wide Compatibility: Ideal for PCB assembly, wiring, and component soldering.

For solder wire with flux rosin core for electronics manufacturing, consistency and reliability are key, making Sn63Pb37 a top choice.

Different soldering tasks require varying solder wire diameters. Below is a breakdown of the most common sizes and their best uses:

Best for: Precision soldering of small SMD components, fine pitch ICs, and delicate electronics.

Advantages: Thin diameter allows for controlled application, reducing the risk of bridging.

Best for: General PCB work, through-hole components, and small connectors.

Advantages: Balances precision and deposition speed, making it versatile for most electronics tasks.

Best for: Medium-sized joints, larger SMD components, and moderate power applications.

Advantages: Faster deposition than 1mm wire while maintaining reasonable control.

Best for: Heavier connections, ground planes, and thicker wires.

Advantages: Higher solder volume per pass, improving efficiency in larger joints.

Best for: High-power electronics, automotive wiring, and large terminals.

Advantages: Rapid solder deposition for high-current applications.

Best for: Industrial soldering, large-scale PCB assemblies, and heavy-duty connections.

Advantages: Maximum deposition rate for bulk soldering tasks.

The solder wire with flux rosin core for electronics manufacturing is indispensable in:

PCB Assembly: Ensures reliable connections for both SMD and through-hole components.

Repair & Rework: Facilitates easy re-soldering of damaged joints.

Automotive Electronics: Provides durable connections resistant to vibration and thermal stress.

Consumer Electronics: Used in smartphones, laptops, and IoT devices for precision soldering.

To maximize the efficiency of your solder wire 63/37 with flux rosin core, follow these best practices:

Use the Right Temperature: 300-350°C (572-662°F) is ideal for Sn63Pb37 solder.

Clean Surfaces First: Remove oxidation with a brass sponge or isopropyl alcohol.

Apply Flux if Needed: Extra flux can improve wetting for difficult joints.

Match Wire Diameter to the Job: Smaller components need thinner wire (0.8mm-1.2mm), while larger joints require 1.6mm-3mm.

Selecting the correct solder wire with flux rosin core is crucial for high-quality electronics manufacturing. Whether you need 0.8mm solder wire with flux rosin core for precision work or 3mm solder wire with flux rosin core for industrial applications, the solder wire Sn63Pb37 with flux rosin core delivers consistent, reliable performance.

By understanding the strengths of each diameter—1mm, 1.2mm, 1.6mm, 2mm—you can optimize your soldering process for efficiency and durability. For professionals in solder wire with flux rosin core for electronics manufacturing, the right choice ensures flawless connections every time.

Invest in high-quality solder wire 63/37 with flux rosin core today and elevate your soldering results!

Contact Information:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: +8613450770997